Solution

Electromobility

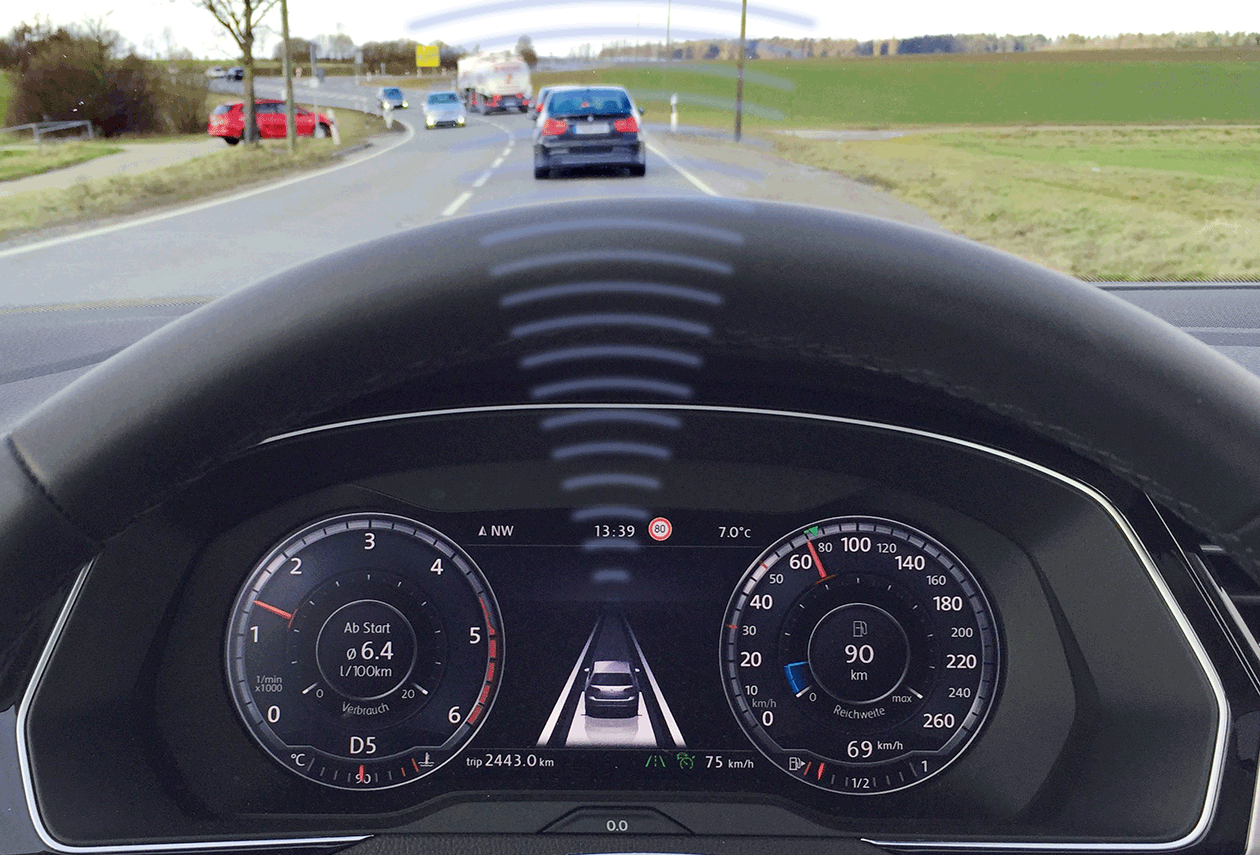

The automotive industry is going through enormous changes. Alternative drives will replace combustion engines in the long term, as it will otherwise be impossible to meet decarbonization targets.

The transformation towards electromobility is already having a demonstrable impact. As a result, many automotive suppliers are facing profound consequences for their production.

Hybrid and battery electric vehicles require elements for converting and monitoring electrical currents and voltages. The components used must withstand a certain load and must be tested to ensure their operational safety.

The automotive industry is going through enormous changes. Alternative drives will replace combustion engines in the long term, as it will otherwise be impossible to meet decarbonization targets.

The transformation towards electromobility is already having a demonstrable impact. As a result, many automotive suppliers are facing profound consequences for their production.

Hybrid and battery electric vehicles require elements for converting and monitoring electrical currents and voltages. The components used must withstand a certain load and must be tested to ensure their operational safety.

Success stories

Case studies

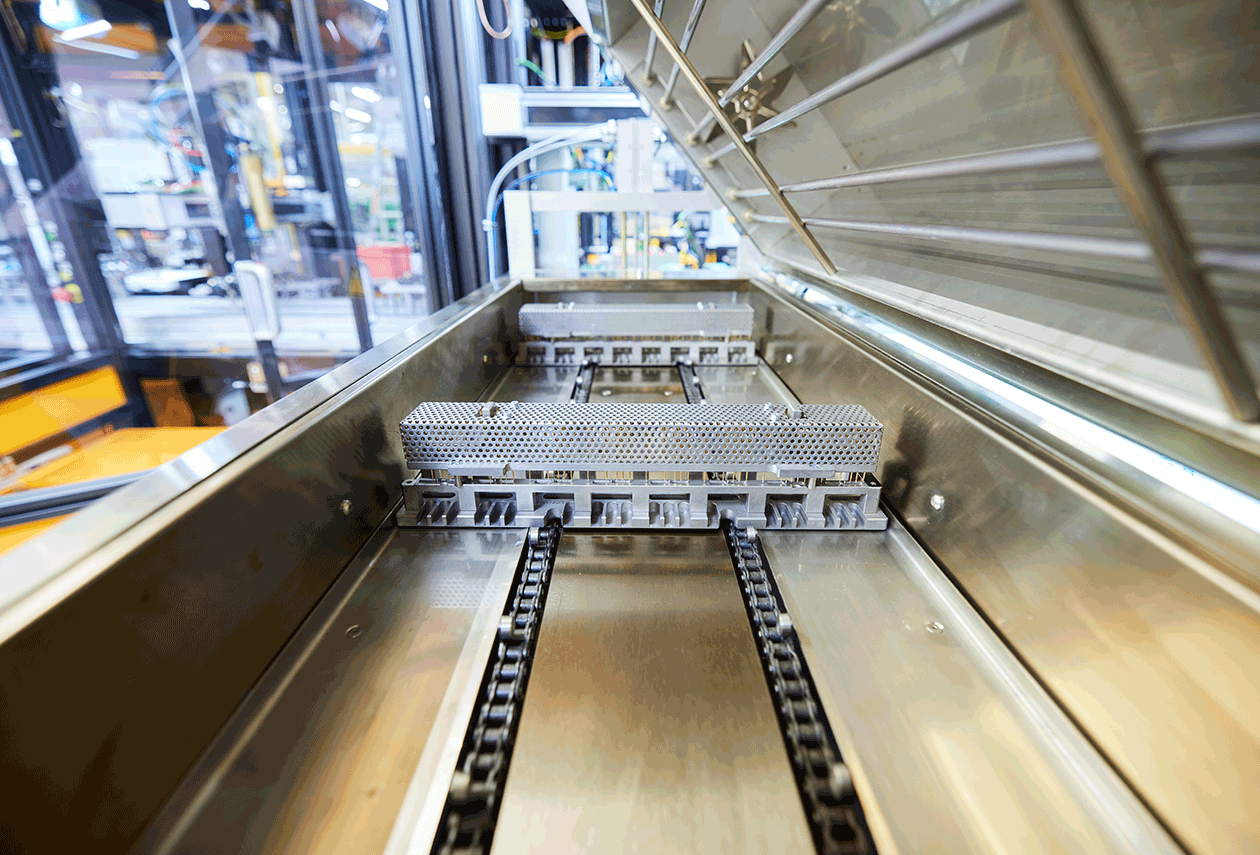

Automated test and assembly lines

You want to guarantee reliable assembly and unconditional functionality?

Considering the growing number of variants and increasing quality requirements, adaptable concepts are needed more than ever. As experienced experts for automotive electronics, we offer you support in developments in electromobility.

Sophisticated electromobility components must be assembled and subsequently inspected and tested under maximum operating conditions. For this purpose, we have developed flexible, customer-specific assembly cells. These allow the integration of additional processes in the event of product changes.

Assembly systems

As a system integrator, we supply scalable production systems for industrial assembly, including intelligent testing technology.

Testing technology

Our test systems for electronics include a variety of test methods ranging from in-circuit testing to end-of-line testing.

Service

Whether through consulting, training or after-sales support: We make sure our systems work on-site right from the start.

Your advantages

Quality assurance

through automated and monitored processes

Wide temperature range from

−40 °C to +140 °C

Flexibility through modular design

Reusable

Volume-scalable

Individually tailored to your requirements

We are true partners. We are there for you personally – as a business, as a contact, and as a service partner. We always communicate at eye level, think agilely, and respond promptly to your needs.

We listen and never stop listening.

Individuality is standard for us: Not only do we create the right solution, but we also stand by your side throughout the entire period of operation with fast and responsible service.

Well thought out solutions

We work out our system concepts creatively and carefully on the basis of your wishes. All the components of our well thought-out solutions are tailored to your production requirements.

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.