Solution

Environmental simulation

Many products must function reliably even under extreme conditions – and despite highly sensitive technology. This is particularly important in markets with safety-critical electronics, such as the automotive industry or medical technology.

Defective components or assemblies can lead to the failure of entire systems, something that always entails high costs and a damaged reputation. Problems in manufacturing processes should therefore be detected as early as possible. This is made possible when employing test methods that simulate real environmental conditions – especially extreme temperatures.

Many products must function reliably even under extreme conditions – and despite highly sensitive technology. This is particularly important in markets with safety-critical electronics, such as the automotive industry or medical technology.

Defective components or assemblies can lead to the failure of entire systems, something that always entails high costs and a damaged reputation. Problems in manufacturing processes should therefore be detected as early as possible. This is made possible when employing test methods that simulate real environmental conditions – especially extreme temperatures.

Success stories

Case studies

Automated test solutions

Do you want to be sure of the functionality and safety of your products?

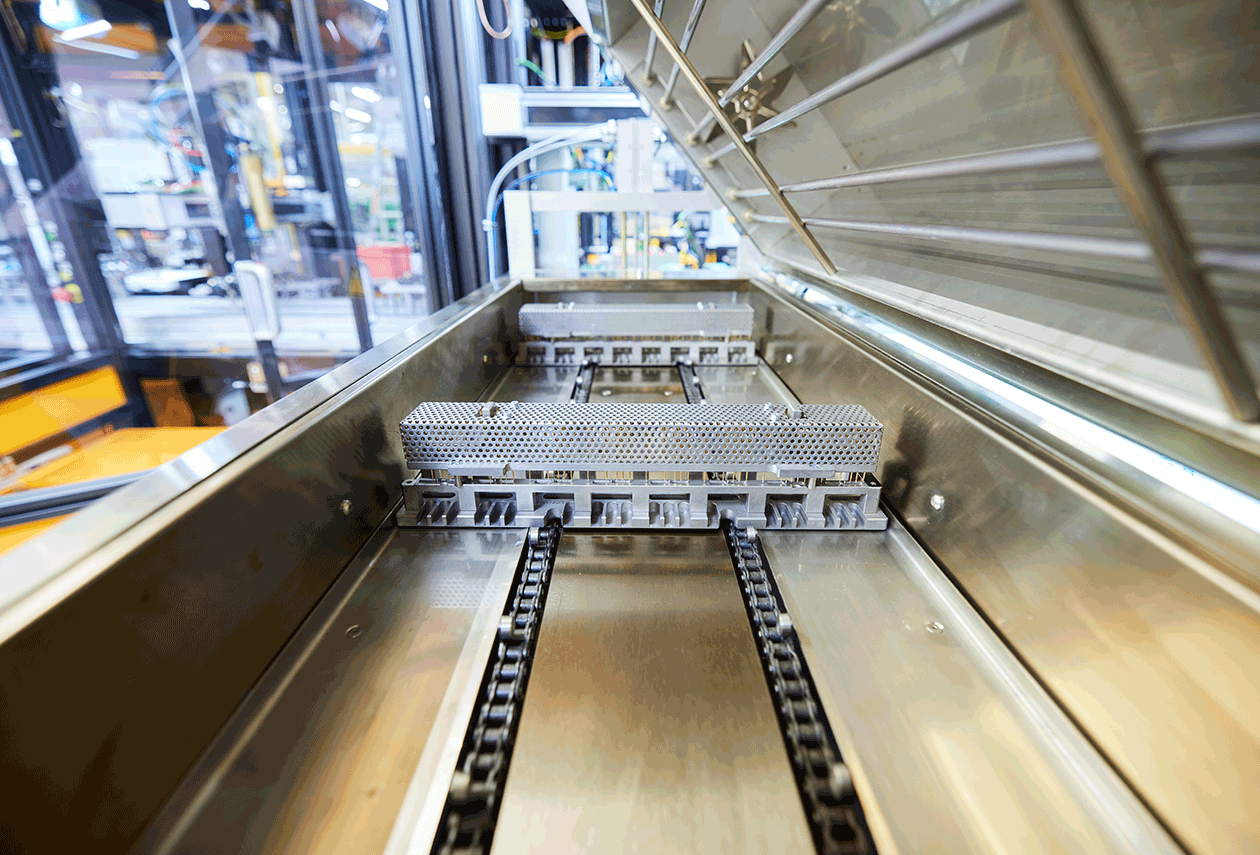

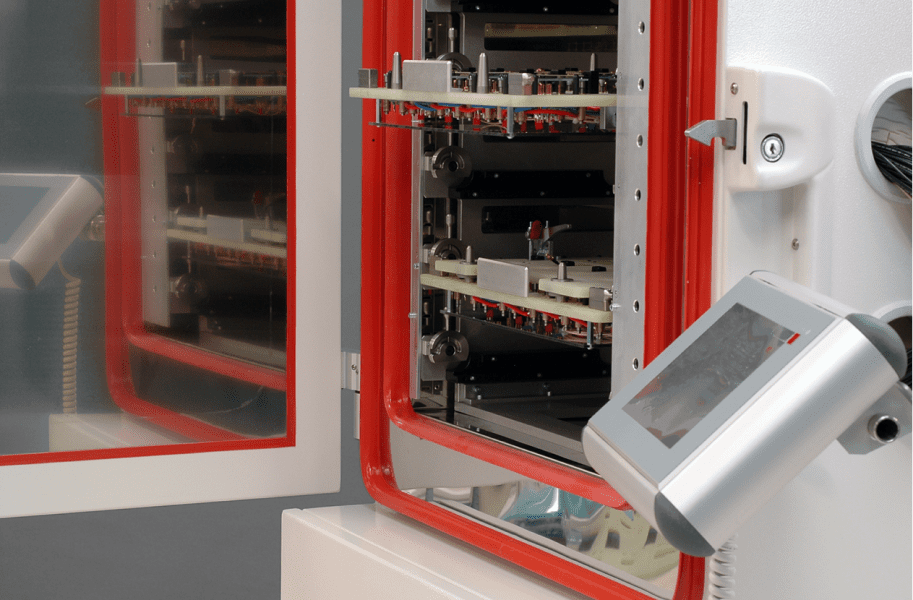

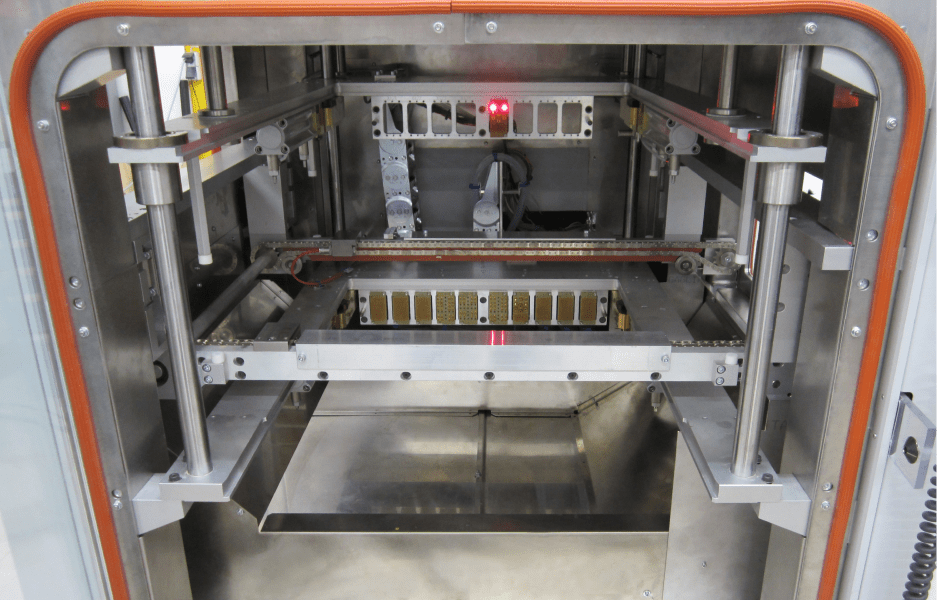

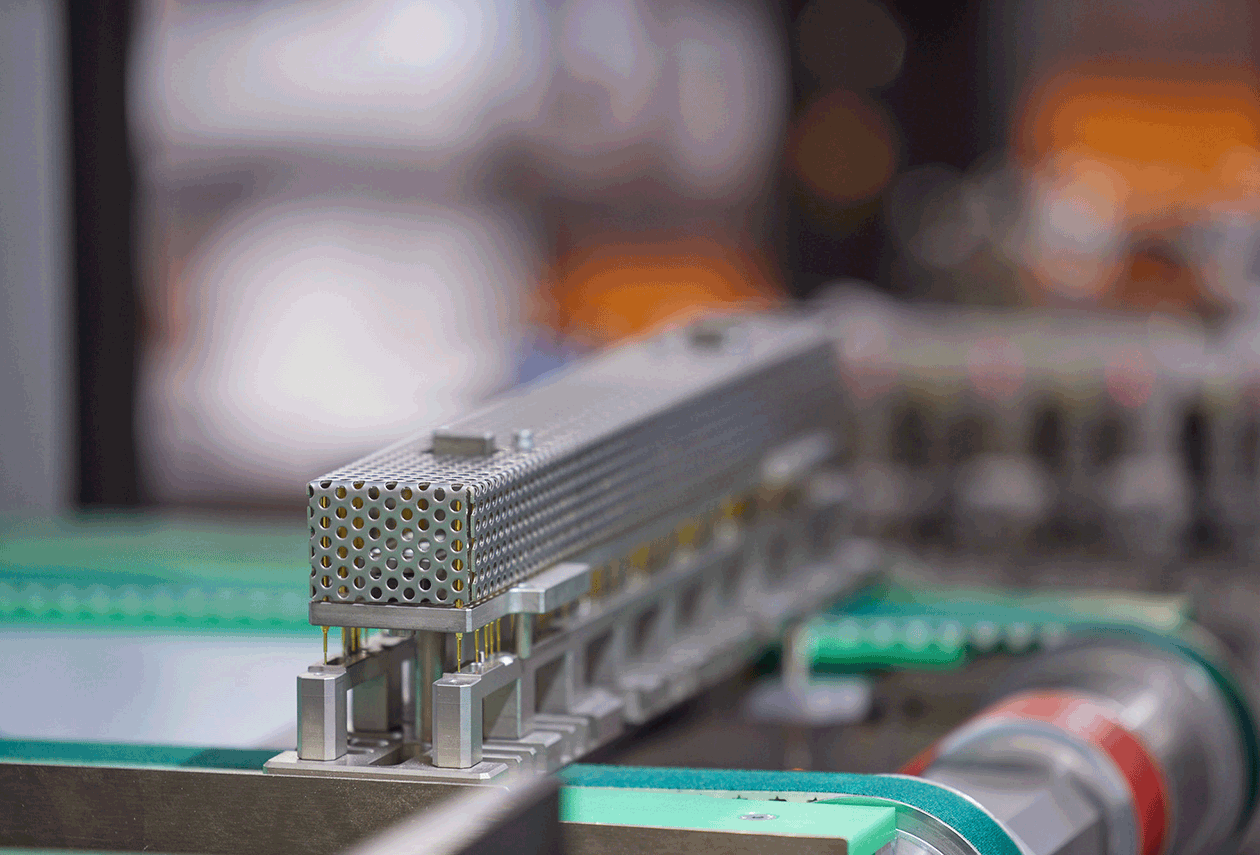

At ENGMATEC, you can obtain needs-based test systems for in-circuit, functional, and end-of-line testing during production. Depending on the requirements, the products are tested by being exposed to various thermal and mechanical stress factors.

In markets with small production volumes, the use of environmental chambers is usually the best solution. If assemblies are produced in high volumes, such as in the automotive industry, continuous testing systems are often a more economical choice. Applications include burn-in, durability, HALT, and HASS testing, calibration, and random testing.

Assembly systems

As a system integrator, we supply scalable production systems for industrial assembly, including intelligent testing technology.Testing technology

Our test systems for electronics include a variety of test methods ranging from in-circuit testing to end-of-line testing.

Service

Whether through consulting, training or after-sales support: We make sure our systems work on-site right from the start.

Your advantages

Temperature profiles of −40 °C to +140 °C

Easy handling

Reliable contacting via low-wear system connectors

Adaptation to customer specifications

Temperature accuracy of ±1 °C possible

Individually tailored to your requirements

We are true partners. We are there for you personally – as a business, as a contact, and as a service partner. We always work at eye level, think agilely, and respond promptly to your needs.

We listen and never stop listening.

Individuality is standard for us: Not only do we create the right solution, but we also stand by your side throughout the entire period of operation with fast and responsible service.

Well thought out solutions

We work out our system concepts creatively and carefully on the basis of your wishes. All the components of our well thought-out solutions are tailored to your production requirements.

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.