Solution

Infotainment displays

High-resolution displays are increasingly serving as the interface between humans and machines. Whether in cars, in homes or on mobile devices, touch displays have taken the place of switches and dials.

This is a rapid development, and the requirements are increasing constantly. Modern vehicles have complex visualization systems that are expected to combine an appearance of high quality with easy-to-use features.

Such systems typically have a similar structure: a backlight, different filter foils, a liquid crystal display module (LCM), a touch sensor, and a cover.

High-resolution displays are increasingly serving as the interface between humans and machines. Whether in cars, in homes or on mobile devices, touch displays have taken the place of switches and dials.

This is a rapid development, and the requirements are increasing constantly. Modern vehicles have complex visualization systems that are expected to combine an appearance of high quality with easy-to-use features.

Such systems typically have a similar structure: a backlight, different filter foils, a liquid crystal display module (LCM), a touch sensor, and a cover.

Success stories

Case studies

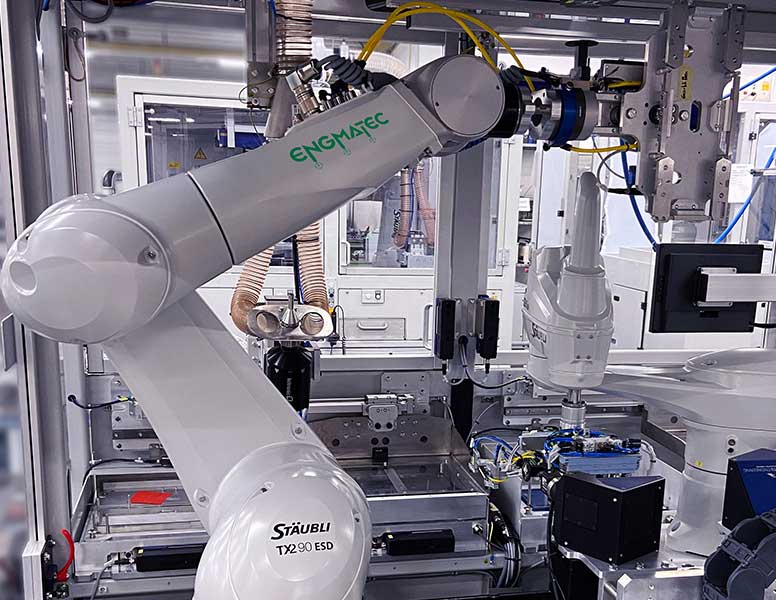

Automated test and assembly lines

Are you looking for solutions for the semi- and fully automated production of display units?

A display consists of several components. To ensure that these come together to form a perfect optical unit, absolute particle purity and precision in joining technology are required. This is the only way to ensure adherence to later gap dimensions and tolerance compensations.

Another challenge is the handling of flexible components and foils, which are formed into a stack in successive joining processes and then installed in respective housings. For us, this is no problem: We can draw on many years of knowledge and extensive expertise that we can put to use for you.

Assembly systems

As a system integrator, we supply scalable production systems for industrial assembly, including intelligent testing technology.

Testing technology

Our test systems for electronics include a variety of test methods ranging from in-circuit testing to end-of-line testing.

Service

Whether through consulting, training or after-sales support: We make sure our systems work on-site right from the start.

Your advantages

Fully automated assembly

of sensitive and unstable components

Maximum positioning and alignment accuracy

High degree of compression

for a small footprint

Handling of widely varying parts

with small batch sizes

Individually tailored to your requirements

Are you looking for solutions for the semi- and fully automated production of display units?

Particle purity and precision

A display consists of several components. To ensure that these come together to form a perfect optical unit, absolute particle purity and precision in joining technology are required. This is the only way to ensure adherence to later gap dimensions and tolerance compensations.

Many years of knowledge

Another challenge is the handling of flexible components and foils, which are formed into a stack in successive joining processes and then installed in respective housings. For us, this is no problem: We can draw on many years of knowledge and extensive expertise that we can put to use for you.

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.