Case Study

Automated display assembly

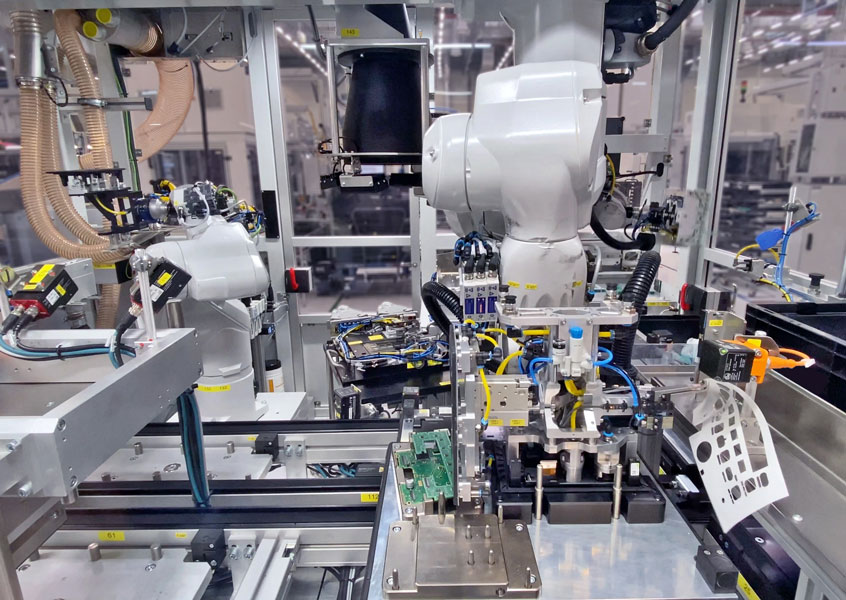

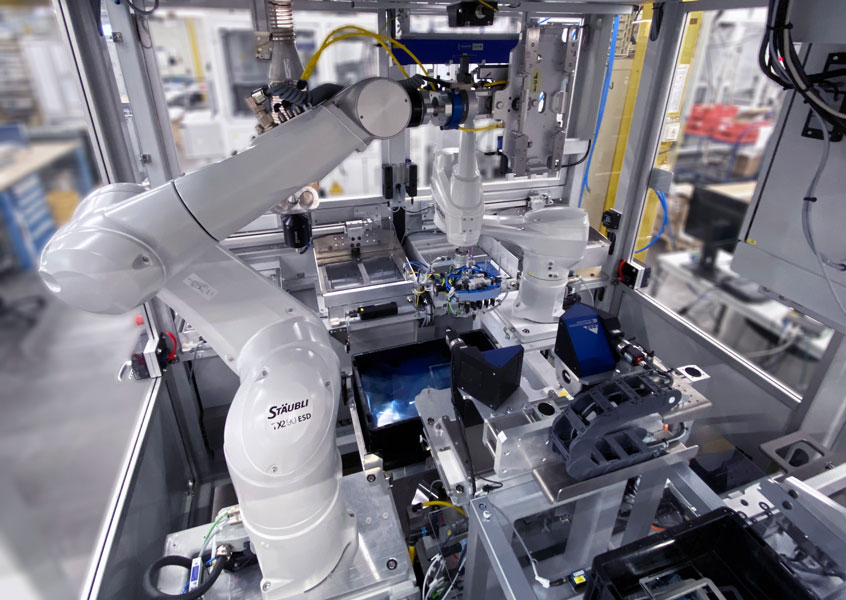

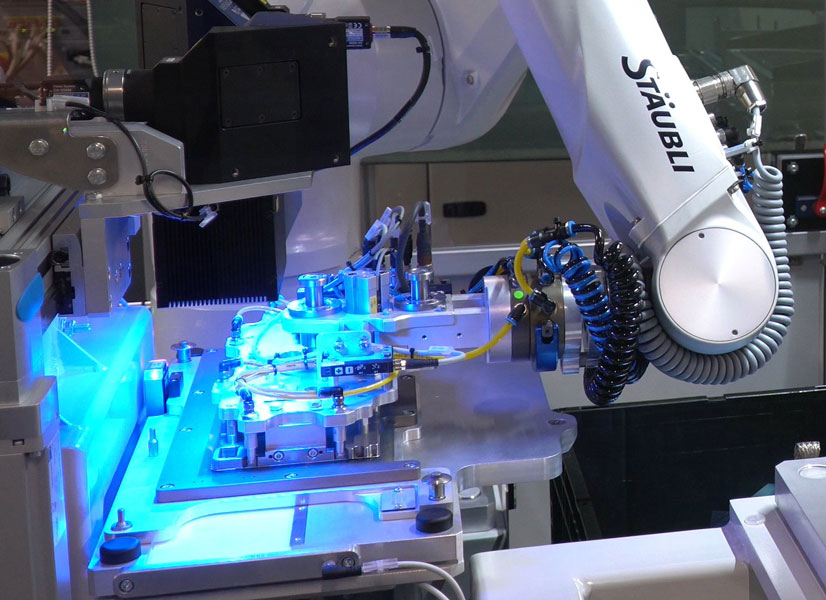

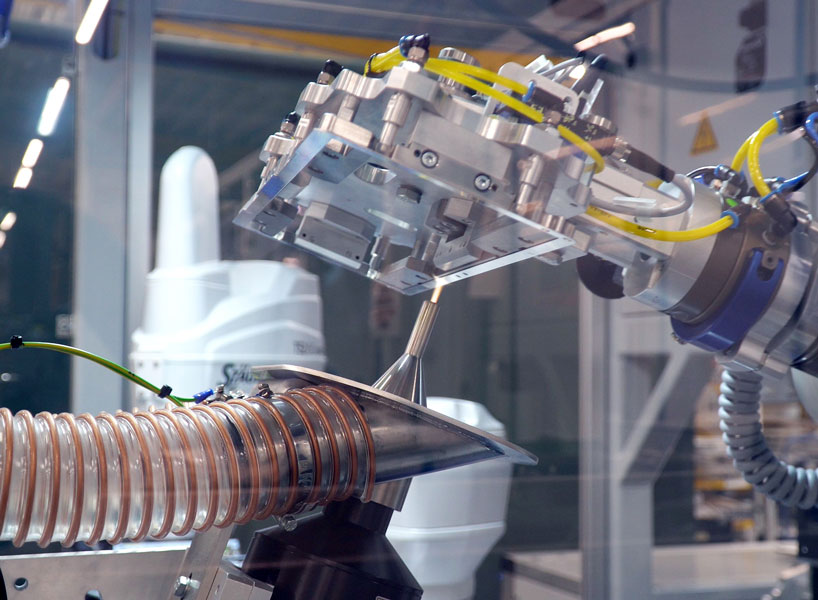

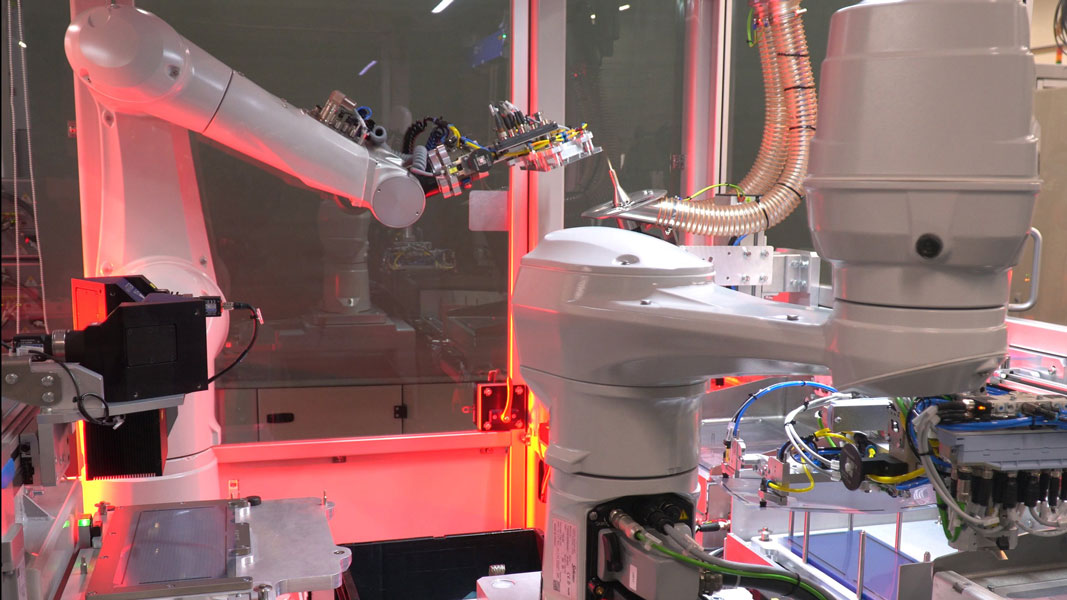

One of our customers required a solution for the automated assembly of infotainment displays of varying sizes for the interior of premium vehicles. The problem: handling flexible and sensitive components like the reflector and diffuser foils or the LED modules and light guides.

Aligning these components with each other with an accuracy within a hundredth of a millimeter in order to ensure a high-quality product was a particular challenge. In order to meet the quality requirements, the manufacturing process also demanded maximum cleanliness. For this reason, the system had to be designed for use in cleanroom conditions.

Cycle time

30 s

per display

Display sizes

9–20

inches

Precision up to

0.01

mm

Our services

ENGMATEC developed a system that already solved the general challenges through the use of ionization, filter, and cleaning modules. The combination of special gripping technology and intelligent camera technology ensured the required precision in joining the individual components with an accuracy of up to 0.01 mm.

Your advantages

Automation of complex processes

Consistent quality

Reduction of manual processes

No contamination due to operator intervention

High precision

Low space requirement

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.