Solution

Industrial electronics

The requirements in the industrial electronics market segment are both demanding and diverse. The wide range of applications for components, assemblies, and devices results in a large number of different variants to be produced in different quantities. This calls for particularly flexible production concepts. Systems must be tailored to the product and scalable so that they can be quickly adapted both to different variants and to different volumes.

ENGMATEC supports you in the introduction of flexible production concepts, such as matrix production or lean production.

The requirements in the industrial electronics market segment are both demanding and diverse. The wide range of applications for components, assemblies, and devices results in a large number of different variants to be produced in different quantities. This calls for particularly flexible production concepts. Systems must be tailored to the product and scalable so that they can be quickly adapted both to different variants and to different volumes.

ENGMATEC supports you in the introduction of flexible production concepts, such as matrix production or lean production.

Success stories

Case studies

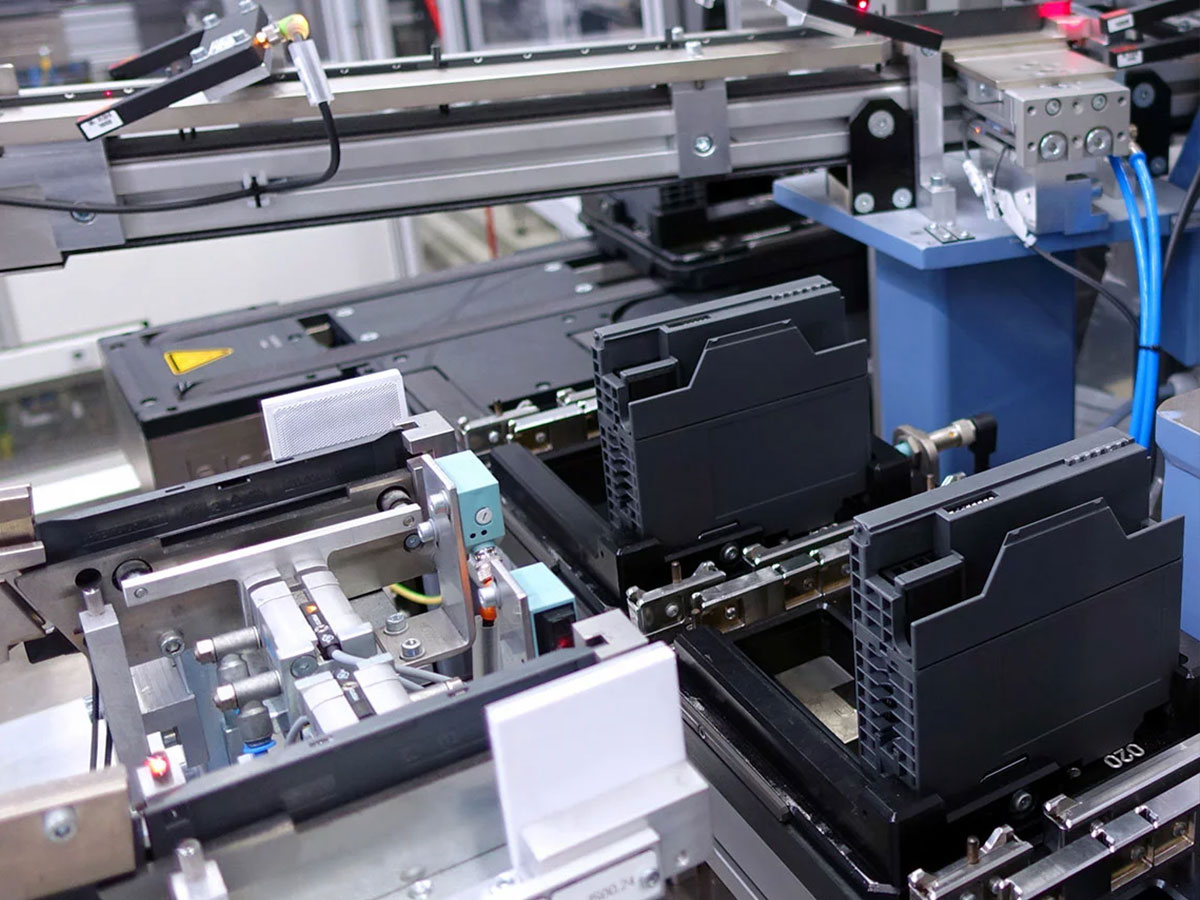

Automated test and assembly lines

Are you looking for flexible automation solutions to optimise your production?

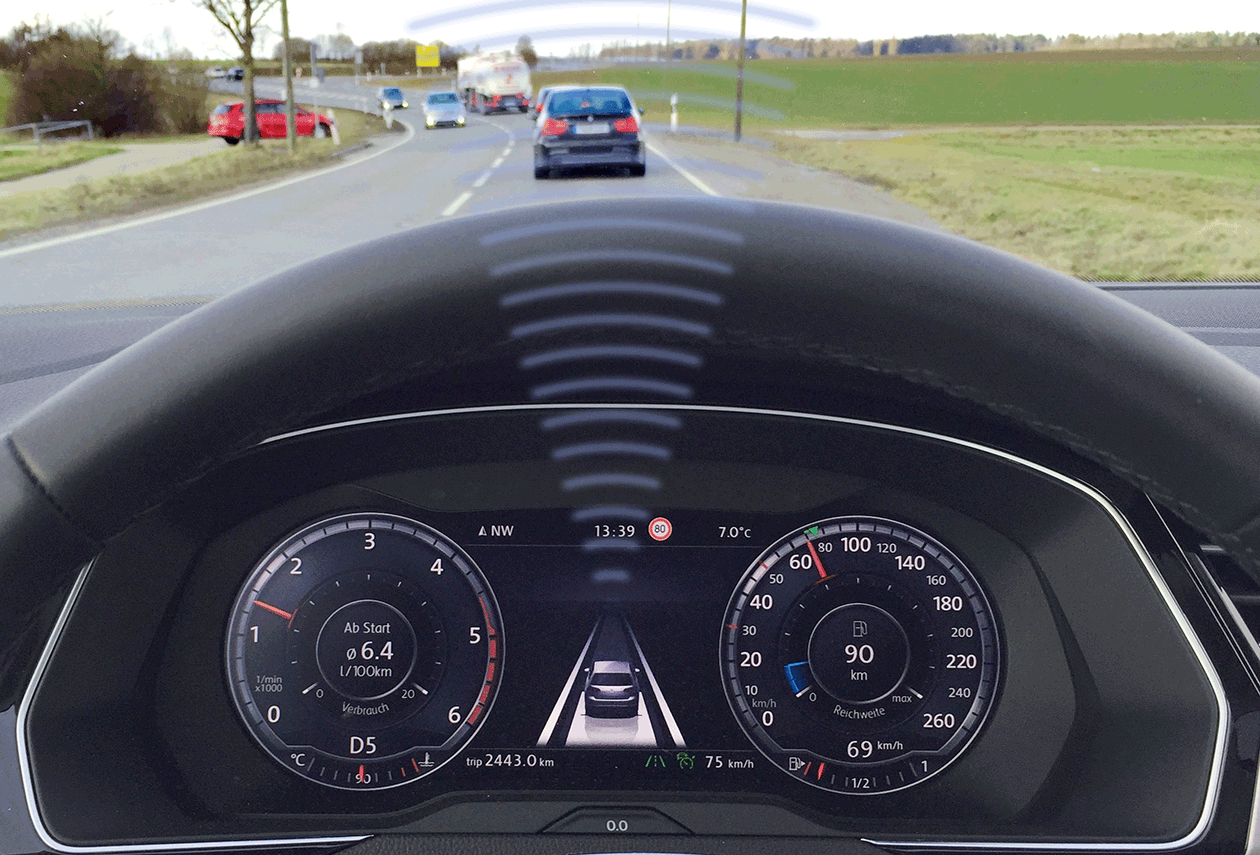

Whether controllers, sensors, drive controllers, electrical and optical switches, safety technology, operating units, measuring and control devices or other electromechanical components – we ensure functional reliability through assembly and testing.

Our sophisticated and flexibly adaptable testing and assembly lines are the answer to changing product variants, high quality requirements, high cost pressure, and changing production outputs.

Our cross-process automation solutions enable you to optimize your production.

Assembly systems

As a system integrator, we supply scalable production systems for industrial assembly, including intelligent testing technology.

Testing technology

Our test systems for electronics include a variety of test methods ranging from in-circuit testing to end-of-line testing.

Service

Whether through consulting, training or after-sales support: We make sure our systems work on-site right from the start.

Your advantages

Solutions for small batch sizes

of diverse variants down to a batch size of 1

Manual linking

of workstations

Low space requirement

due to consolidation of process and handling

High flexibility

with customer-specific adaptations

Special designs

based on the needs of medium-sized companies

Manual workstations

with integrated test solutions

Individually tailored to your requirements

We are true partners. We are there for you personally – as a business, as a contact, and as a service partner. We always work at eye level, think agilely, and respond promptly to your needs.

We listen and never stop listening.

Individuality is standard for us: Not only do we create the right solution, but we also stand by your side throughout the entire period of operation with fast and responsible service.

Well thought out solutions

We work out our system concepts creatively and carefully on the basis of your wishes. All the components of our well thought-out solutions are tailored to your production requirements.

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.