Case study

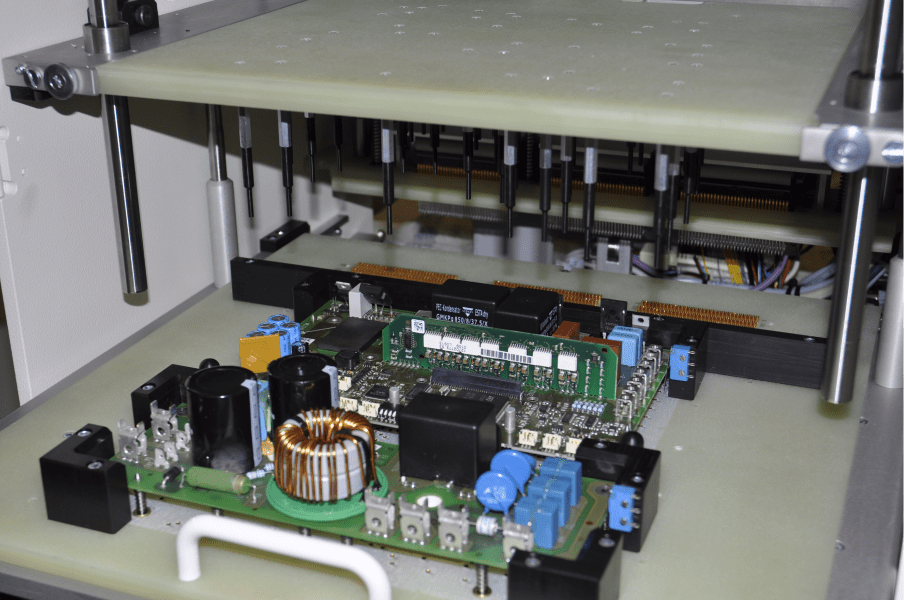

Drawer fixture for engine control units

One of our customers required a stand-alone test system for testing drive controllers. In order to integrate the system into a standardized lean assembly concept, a very compact design was required.

For this purpose, ENGMATEC developed a combination of a drawer fixture and a measuring equipment rack. In this unit, the necessary test equipment is integrated directly in the lower area of the fixture. It was designed as a pneumatic 2-stage test fixture for the in-circuit and functional testing of PCB modules.

Test points up to

1,400

pneumatic contacting

on both sides

Footprint

38x28cm

for testing several

single products

Multiple test up to

5

different flat modules

Our services

The test fixture has a usable area of 310 x 280 mm for contacting one or more single PCBs. Precise ball bearing guides ensure the highest contacting accuracy in this system. The toggle lever mechanism used allows high contact forces and a very precise, parallel-acting contact stroke. Pneumatic contacting on both sides is also possible.

Your advantages

Quick change

of DUT holders and contact pin carrier plates

High contacting accuracy and forces

Optimum accessibility

Compact design

Easy integration

into existing production environments

Low space requirement

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.