Case study

Fully automated testing of printed circuit boards

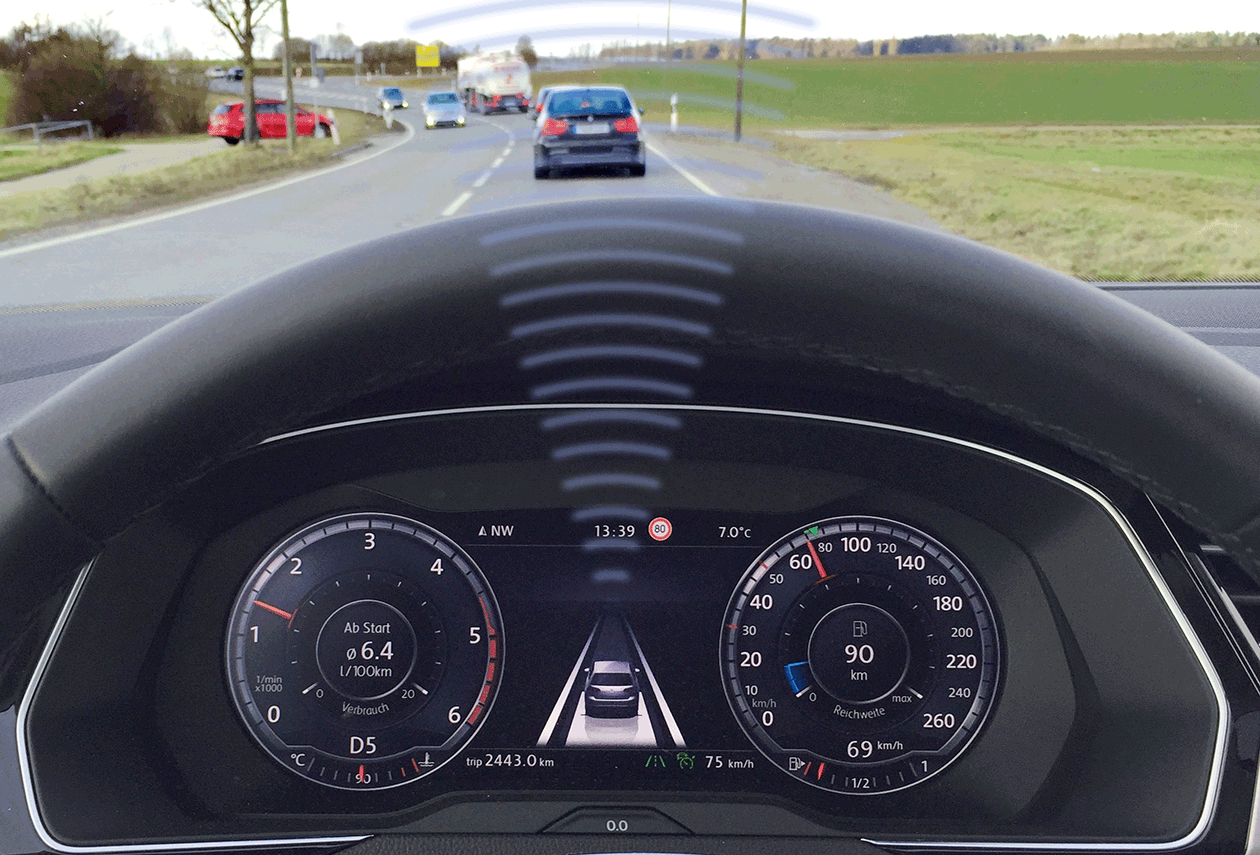

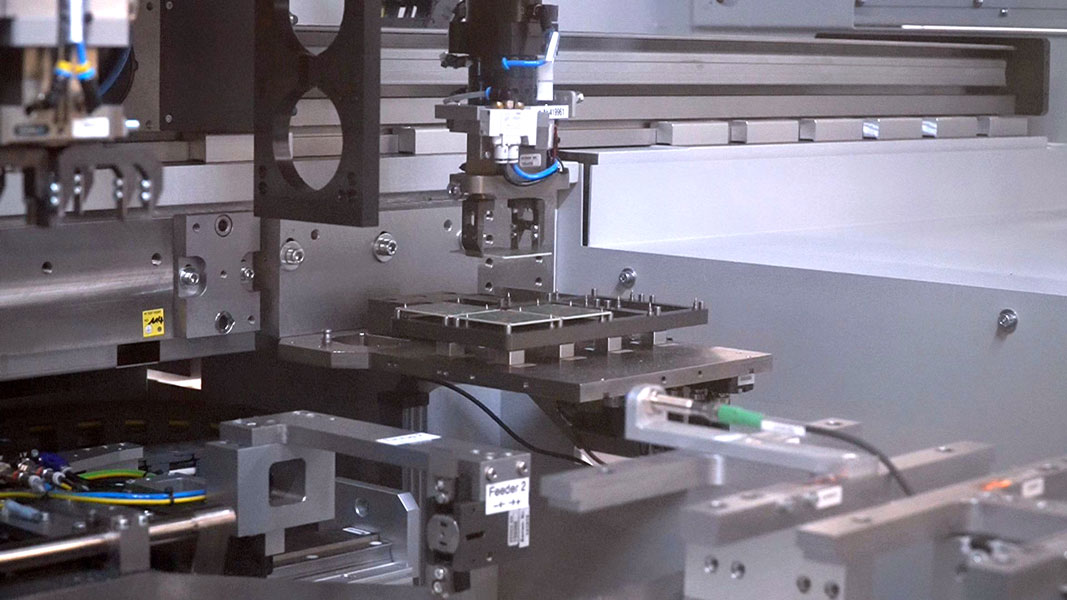

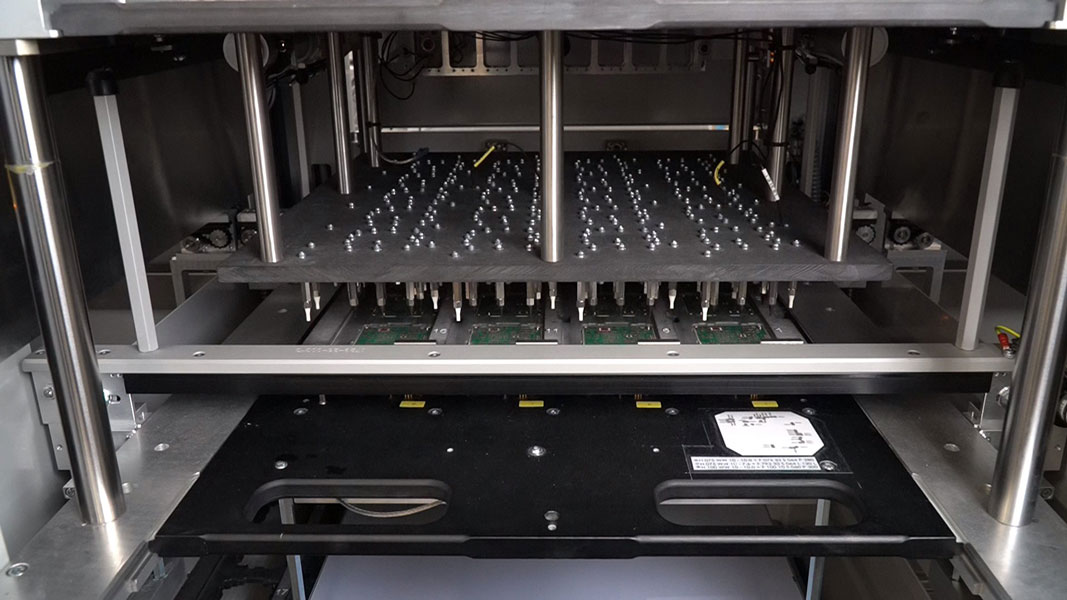

A customer came to us with an order for the fully automated testing of printed circuit boards. These form the core of a radar sensor and must therefore meet the highest quality and safety requirements.

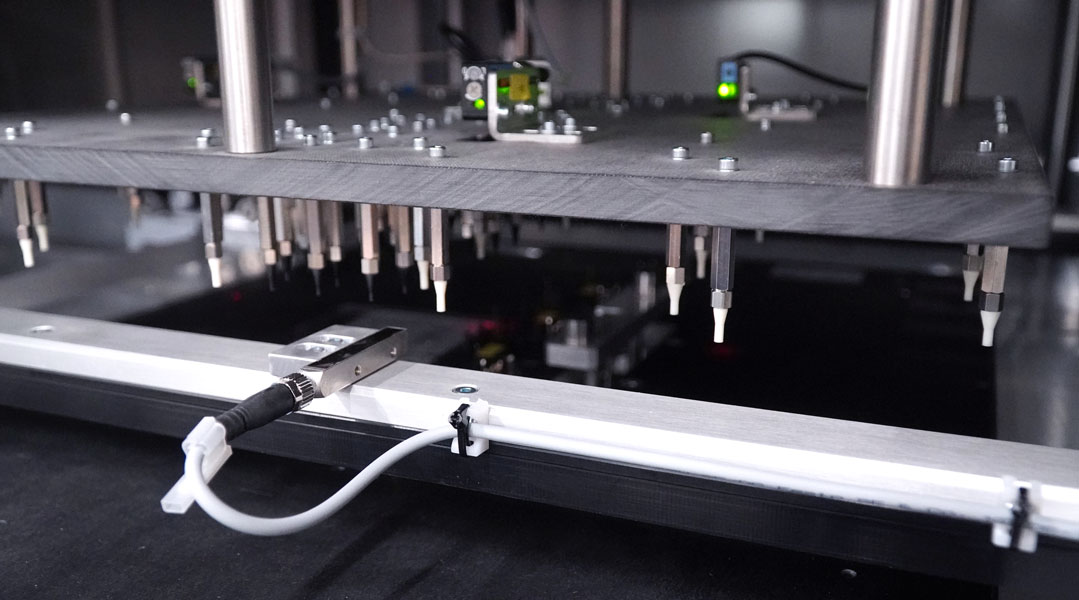

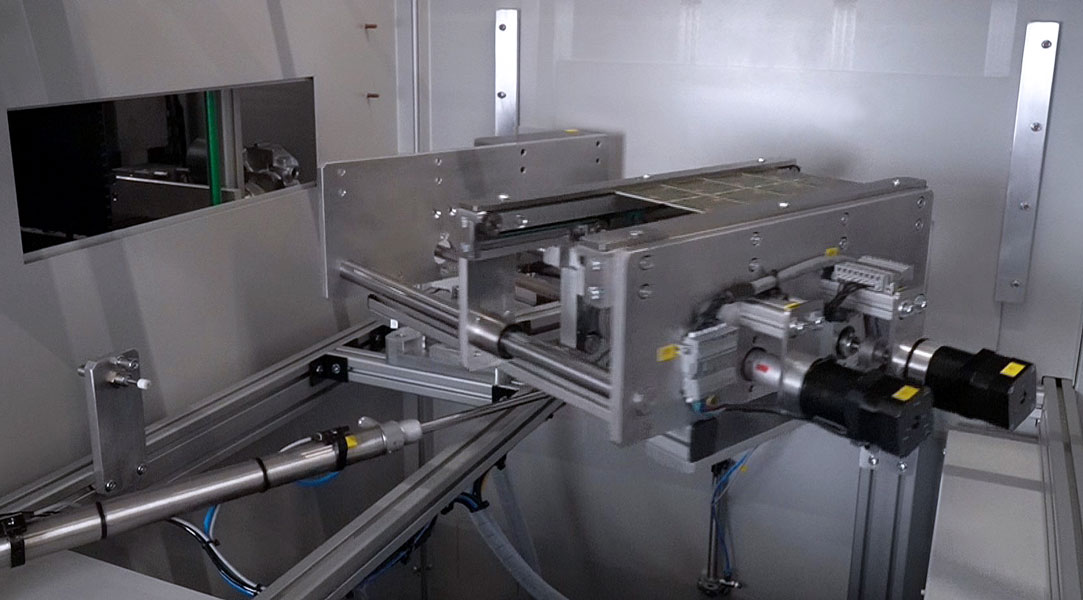

Given the high volume in which they are manufactured, the main focus was on the cycle time, which had to be reduced as much as possible. The automation concept was further developed over several system generations, so that we were able to reduce the cycle time per individual printed circuit board to 3 seconds. Another advantage is that the complete line has a setup time of less than 10 minutes.

Due to the modular concept, a system for small volumes would also be feasible.

The concept is based on many years of experience and many generations of these lines. Exchangeable product-specific contacting allows different PCBs to be tested – whether for radar sensors, control units, or other electronics.

Cycle time

3s

due to parallel processes

and multiple testing

Traceability

100%

due to integration

with traceability system

Self-sufficiency

>1h

due to sufficient buffer

capacities for the material

Our

services

To generate a cost-effective solution for the customer, ENGMATIC employed standardized board handling modules and test handlers and integrated depaneling machines. Various contacting concepts, such as full-surface contacting or step operation, were employed both to satisfy the cycle time requirement and to lower the capital expenditure.

Your advantages

Low cycle time

Standardized, scalable modules

Individual integration with measuring systems

No contamination due to operator intervention

Traceability

Flexible use for different products

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.