End-of-line-Test (EOL Test)

What is an End-of-Line-Test?

An end-of-line test is a test procedure carried out at the end of the production line to ensure that a manufactured product meets the specified quality standards and fulfils the specified functions and performance. This final test is used to identify possible faults or defects before the product is packaged and delivered to the customer. In this way, the quality of the product can be improved and customer satisfaction guaranteed.

An end-of-line test is a test procedure carried out at the end of the production line to ensure that a manufactured product meets the specified quality standards and fulfils the specified functions and performance. This final test is used to identify possible faults or defects before the product is packaged and delivered to the customer. In this way, the quality of the product can be improved and customer satisfaction guaranteed.

What is special about end-of-line tests?

The EOL test comprises a defined check of specified parameters of the entire product or its key components. The specific test procedures can vary depending on the product and industry. The end-of-line test systems can include electrical tests (classic in-circuit test), functionality tests (function test), stress tests, performance tests or other relevant tests (displacement, force, colour, symbolism, labelling, etc.) to ensure product quality and functionality. Specialised testing facilities and equipment are used to carry out these tests.

What is this test important for?

The EOL test is important to ensure that products meet the specified standards and requirements before they are launched on the market. It minimises the risk of rejects, warranty claims and customer rejections. It also helps to ensure product safety for the customer and to minimise any liability risks. This test is therefore an integral part of effective testing systems.

For which industries is an EOL test essential?

An EOL test is essential in various industries, particularly in the automotive industry, electronics industry, medical technology and also in building services. In the automotive industry, for example, electronic components are subjected to an EOL test to ensure that all systems and components are functioning properly. In the electronics industry, products such as smartphones, sensors and control units are tested for their performance and reliability. In medical technology, medical devices are subjected to an EOL test to check their accuracy and functionality in the manufacturing process.

Quality criteria for an end-of-line tester

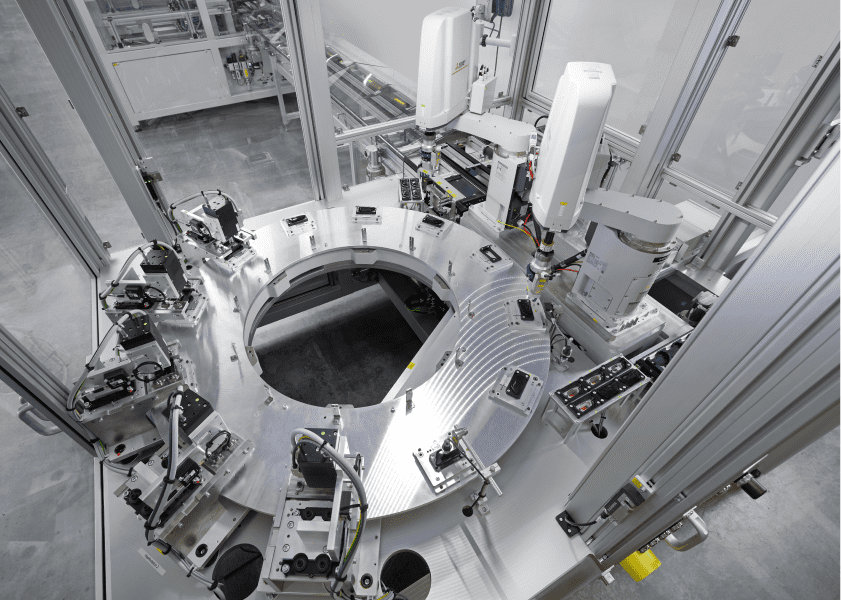

An effective EOL test faces various challenges. The system must deliver reliable and precise test results, be easy to operate and be able to be seamlessly integrated into the existing production line. At the same time, high productivity and efficiency play a key role in optimising production work flow. Depending on the production volume and speed, the system must be able to carry out tests in a reasonable period of time without slowing down the production line.

A key capability is to be able to flexibly adapt or configure test sequences in order to smoothly support product changes or changes in production.

Application examples for end-of-line test systems

In the automotive industry, the end-of-line tester is used to test the electronic systems of a vehicle. This includes testing sensors and other important components. EOL tests are always mandatory for components that contribute to personal and occupant protection.

Cases

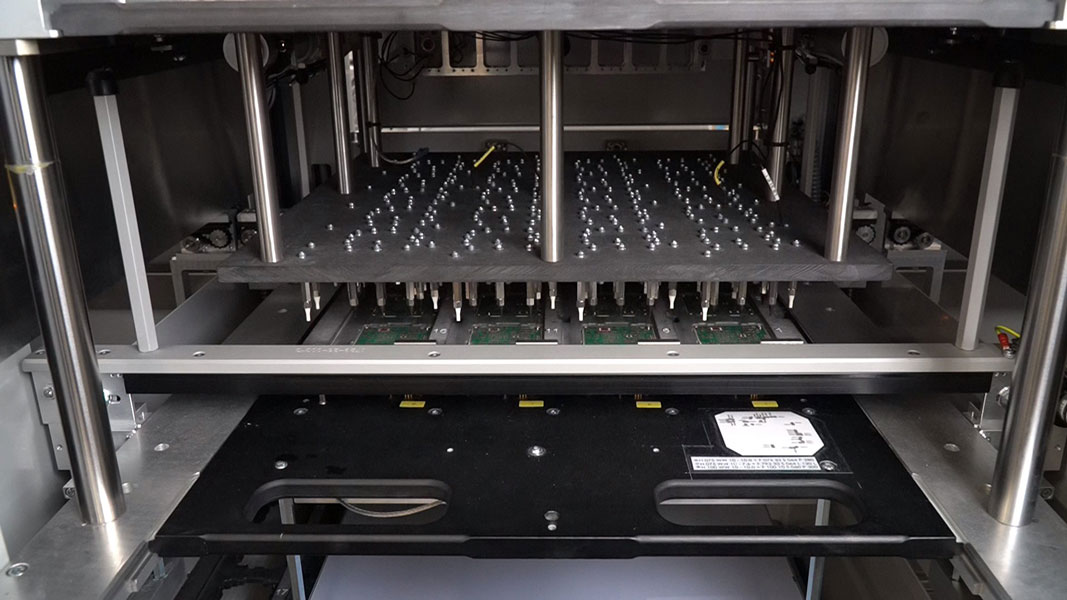

Case 1: Testing of printed circuit boards

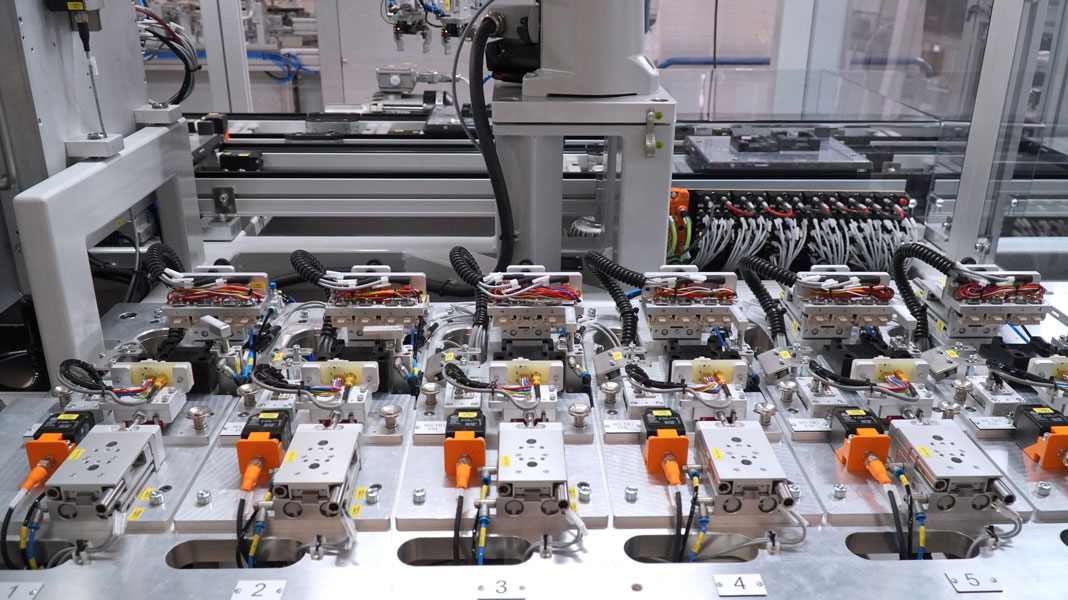

A customer came to us with an order for fully automated testing of printed circuit boards. They form the centrepiece of a radar sensor and must therefore meet the highest quality and safety requirements. The end-of-line test is therefore a basis for realising autonomous driving.

With the high production volume, the main focus was on a short cycle time. We were able to reduce the cycle time per PCB to 3 seconds. Different PCBs can be tested using interchangeable product-specific contacting - whether for radar sensors, control units or other electronics.

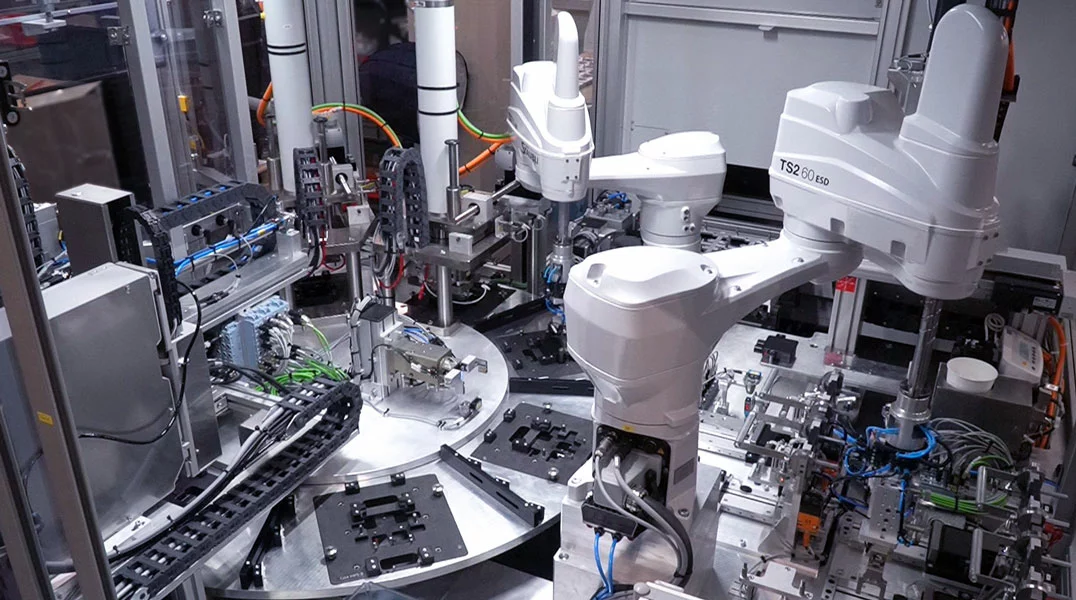

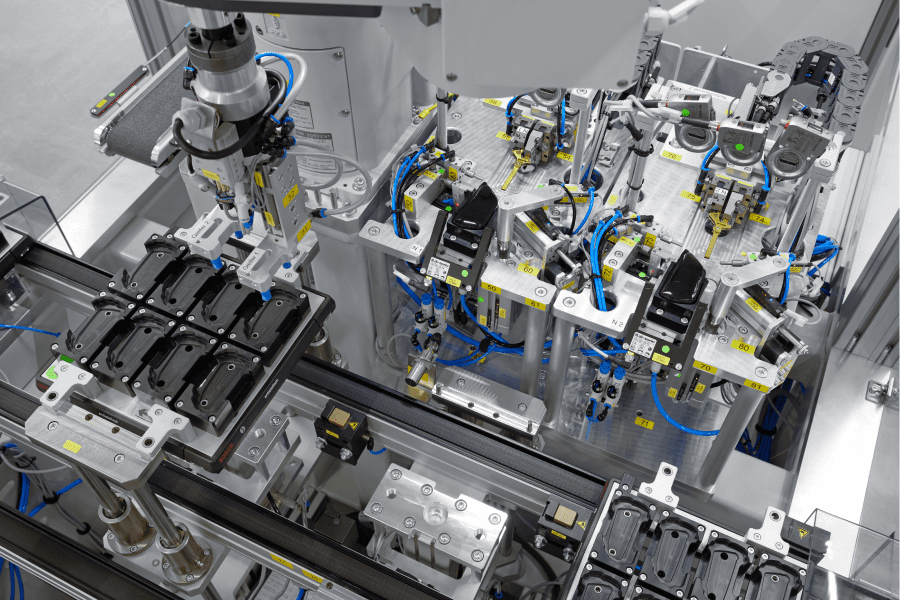

Case 2: Control unit for driver assistance systems

Another customer commissioned ENGMATEC with the automated assembly and end-of-line testing of a control unit for driver assistance systems. The system was also to check for leaks and perform other processes such as packaging and labelling. The test had to take place in a test environment shielded from the environment (HF test).

Case 3: End-of-line test of a heating control unit

We have realised a stand-alone device for the end-of-line test of a heating control system for a customer in the building services sector. The visual and haptic EOL test is carried out very efficiently and economically during loading and unloading.

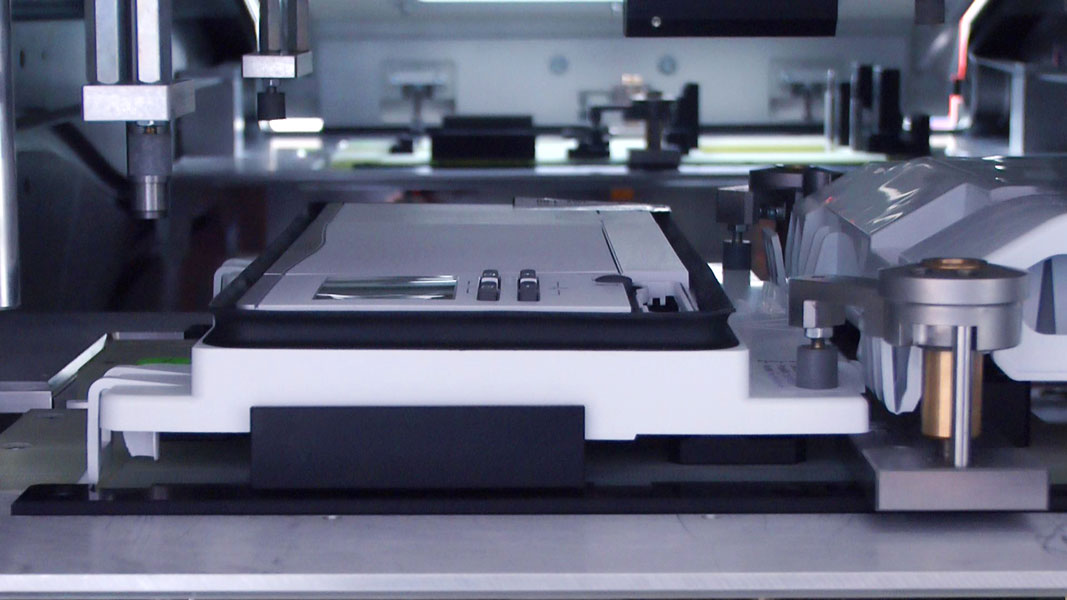

Case 4: Testing of a car key

To ensure the function of a vehicle key, ENGMATEC has developed an EOL solution that checks the radio key in a shielded test environment. In addition to a precise haptic test of each individual key, the quality of the keys is checked visually.

What services does Engmatec offer?

Engmatec is a global partner for EOL testing services. This primarily includes the development and provision of customised test systems that meet specific customer requirements. ENGMATEC supports customers in integrating the systems into the existing production environment and offers training and technical support.

The range of services covers a variety of test procedures, including

- In-circuit test

- function test

- Load tests

- Performance tests

- Environmental test

- Leak test

- Identification tests

- Other tests relating to distance, force, colour, symbols, labelling, etc.

Why Engmatec

EOL test systems from Engmatec are characterised by outstanding quality, reliability and precision. They are used worldwide in industrial companies of various sizes and sectors. As a flexible test solution, they can be seamlessly integrated into even complex production lines and guarantee maximum efficiency. So that there are no limits to your production.

Not only the quality of our test systems is first-class, but also our support. If required, we can accompany you throughout the entire process. From planning and installation to maintenance of your EOL test systems.

Do you have further questions about our products or our service? Contact us at any time.

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.