Assembly system

An assembly system is a specialised production system that is used for the manual, semi-automatic or fully automatic assembly or production of components. An assembly system can map several steps of a manufacturing process using various stations. This automates processes, reduces manufacturing costs, increases production speeds and guarantees consistent conditions and quality.

How is an assembly system constructed?

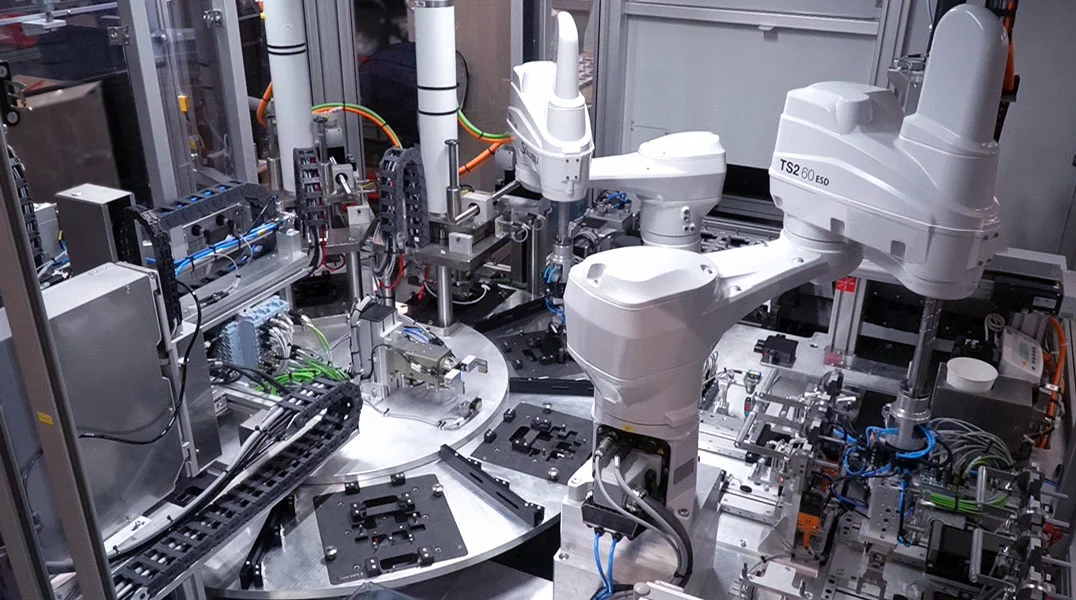

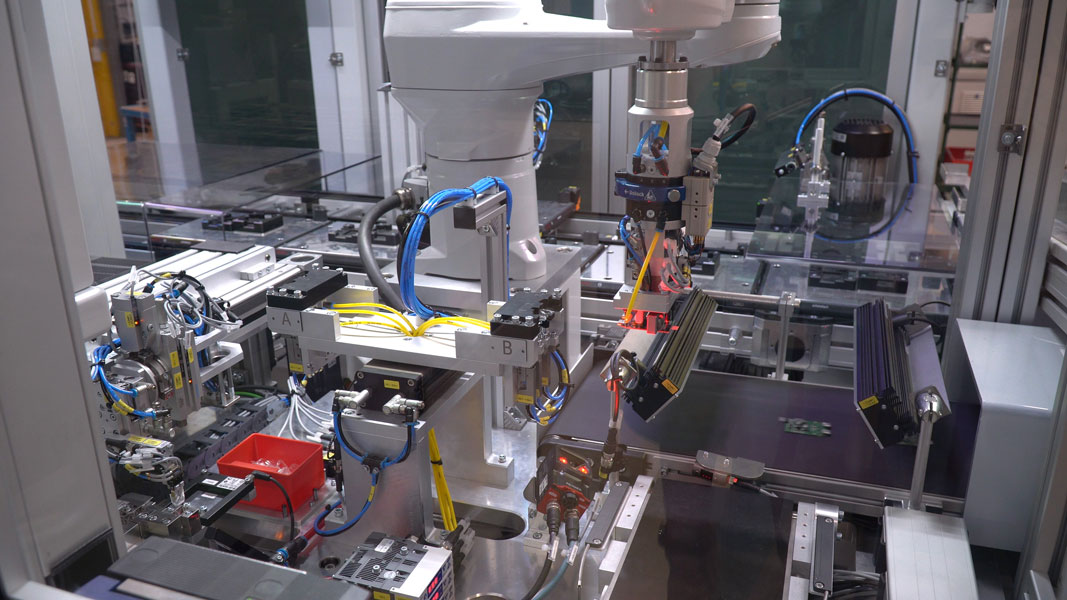

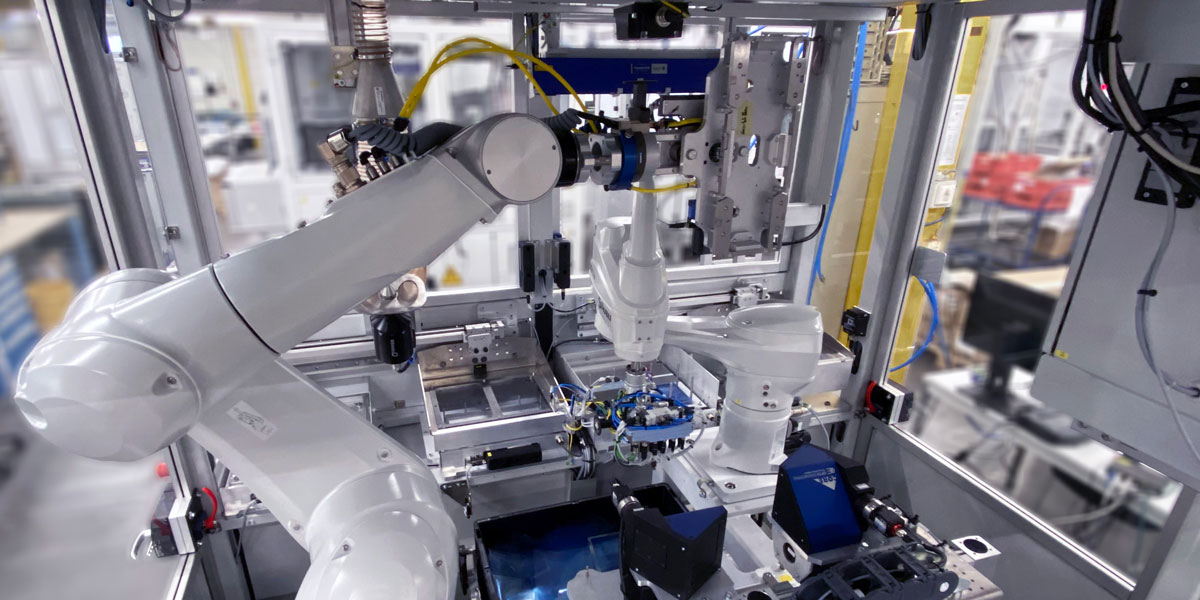

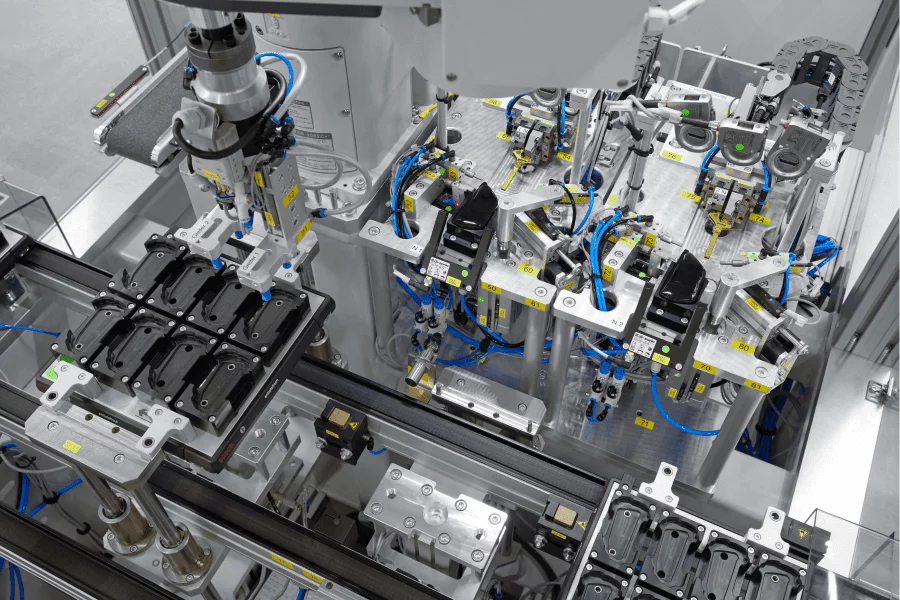

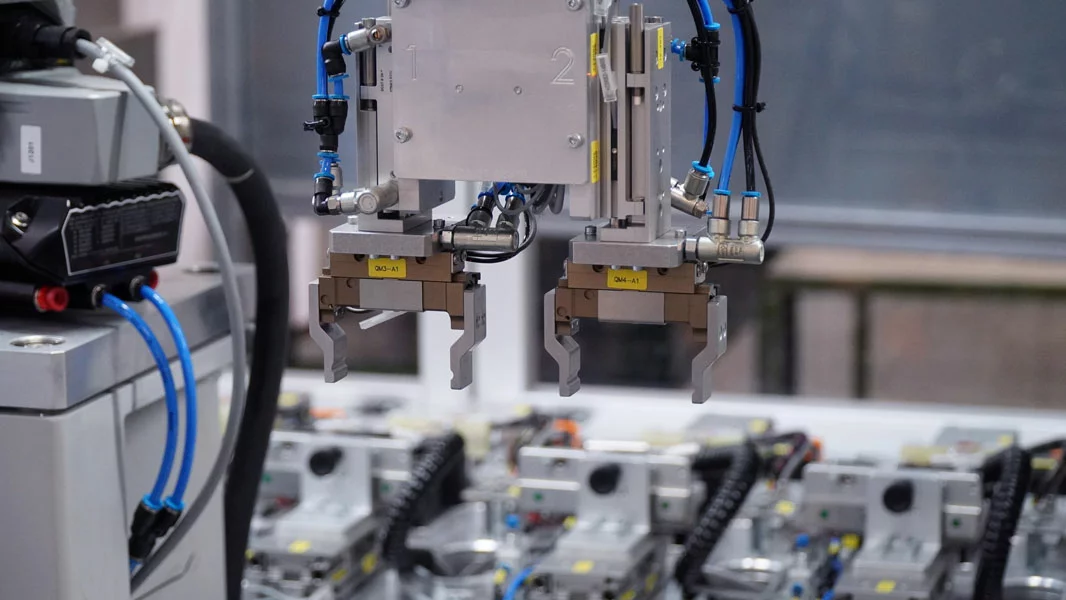

An assembly system is made up of one or more process modules and consists of a large number of components. These include robots, conveyor belts, assembly equipment, testing equipment, cameras, sensors and control systems. In addition to the pure mechanics, the control technology is an essential component that ensures that processes are coordinated and monitored.

An assembly system is made up of one or more process modules and consists of a large number of components. These include robots, conveyor belts, assembly equipment, testing equipment, cameras, sensors and control systems. In addition to the pure mechanics, the control technology is an essential component that ensures that processes are coordinated and monitored.

Types of automated

assembly systems

What types of automated assembly systems are there?

There are many different types of assembly systems, which differ mainly in their degree of automation and modifiability. The spectrum ranges from interlinked individual workstations, rotary indexing systems and robot systems to inline concepts with longitudinal indexing assembly machines. Depending on the task, assembly systems are realised as manual workstations, rotary indexing tables, interlinked standard cells or, for example, as complete inline production systems.

The optimum automation depends on various factors such as the number of units, cycle or cycle time, complexity of the processes, variety of types or location. The trend is towards variant-flexible, modifiable and reusable production systems in order to secure investments for as long as possible.

Fully automatic assembly lines

Fully automated production lines are a type of automatic assembly machine used in the manufacturing industry. Various processes, such as assembly, sorting or soldering, are organised in one line in order to increase production efficiency.

Semi-automatic assembly systems

In semi-automatic assembly systems, some of the assembly processes are automated while others are carried out manually.

What is the importance of assembly systems?

Assembly systems are key components in electronics production. Especially for the mass production of electronic devices such as mobile phones, sensors, displays, controllers and many automotive electronics components. Electronics production in particular can be very challenging due to its complex nature and high precision requirements. Parts and components must be positioned very precisely to ensure faultless function.

Assembly systems can not only increase precision, but also accelerate production speed and thus reduce overall production time. Flexible assembly systems that can be customised for different products and requirements are often needed. They enable rapid changeover and adaptation to changing production requirements.

Systems designed according to the matrix production concept offer particular advantages in terms of adaptability, efficiency and cost savings. Matrix production allows different product variants to be manufactured on the same production line. This maximises the capacity utilisation of the production facilities and makes it possible to react more quickly to market changes and customer preferences.

The use of sensibly and functionally developed assembly systems can therefore make a significant contribution to increasing a manufacturer’s competitiveness on the market.

Assembly systems from Engmatec

Engmatec is a specialist and experienced partner for assembly systems. Specialising in electronics and mechatronics production, our products are used all over the world. Our automation solutions bring together a wide variety of manufacturing processes. We are particularly strong in the combination of automated assembly systems and special machines with professionally integrated end-of-line testing technology, especially in the electronics sector. Our core expertise lies in particular in sophisticated test technology.

Manual process module

The system with manual insertion area is used for low quantities and serves to support employees.

more

Semi-automatic process module

Components with a scalable degree of automation guarantee flexible production figures.

more

Fully automatic process module

Various processes from feeding to AOI can be interlinked and designed as a fully automatic line.

more

Assembly processes in our automation systems

ENGMATEC takes over the assembly of your products and integrates all the necessary processes such as feeding, material handling, positioning, assembly and testing.

Our feeding systems enable both manual and automated feeding of components, whether in organised form in defined transport containers or as bulk material. ENGMATEC offers intelligent handling systems specifically for PCBs and assemblies. Depending on the requirements, we integrate either a product carrier circulation system, a rotary indexing table, robot handling or axis and gripper systems.

In addition to component handling, assembly systems include customised process modules for joining, adjusting and labelling. Processes such as weighing and dosing, greasing, dispensing or soldering are also integrated. Packaging stations are often found at the end of a system.

Testing

To give you the certainty that your product has been assembled correctly, we integrate an end-of-line test directly into the assembly system. This test includes both electrical and mechanical tests, such as haptic tests. We also use special test methods such as leak or high-frequency tests, as well as visual inspections.

These tests ensure maximum safety for you and your product. You can rest assured that every single product has been thoroughly tested and meets quality standards before it leaves the assembly line. This gives you the certainty of a flawless end product.

Anbindung Traceability

We offer a connection to your traceability system so that you can track every production step. Our customised solution provides information on assembled parts, process parameters and the results of the end-of-line inspection. This enables improved traceability and transparency in your production.

Your advantages

Combined assembly and testing expertise

Customized solutions

Economic strategies

Fault reduction in the production process

Reduced personnel costs due to reduced need for manpower

Transparent production

Why Engmatec

We know what we can do. And we continue to develop with you. Thanks to proven assembly technology and efficient assembly systems, we achieve optimised production processes and the highest quality standards for our customers.

30 years of experience as a competent partner for automation solutions specialising in electronics & mechatronics production

Testing and assembly expertise from a single source

Maximum flexibility in finding and realising solutions

Project management based on the automotive standard

End-to-end ERP and product lifecycle management to support project management

Maximum transparency in the production process

Minimisation of errors within your production

Significant cost savings through reduction of personnel requirements

Customised service tailored to your needs

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.