Products

Interchangeable fixtures

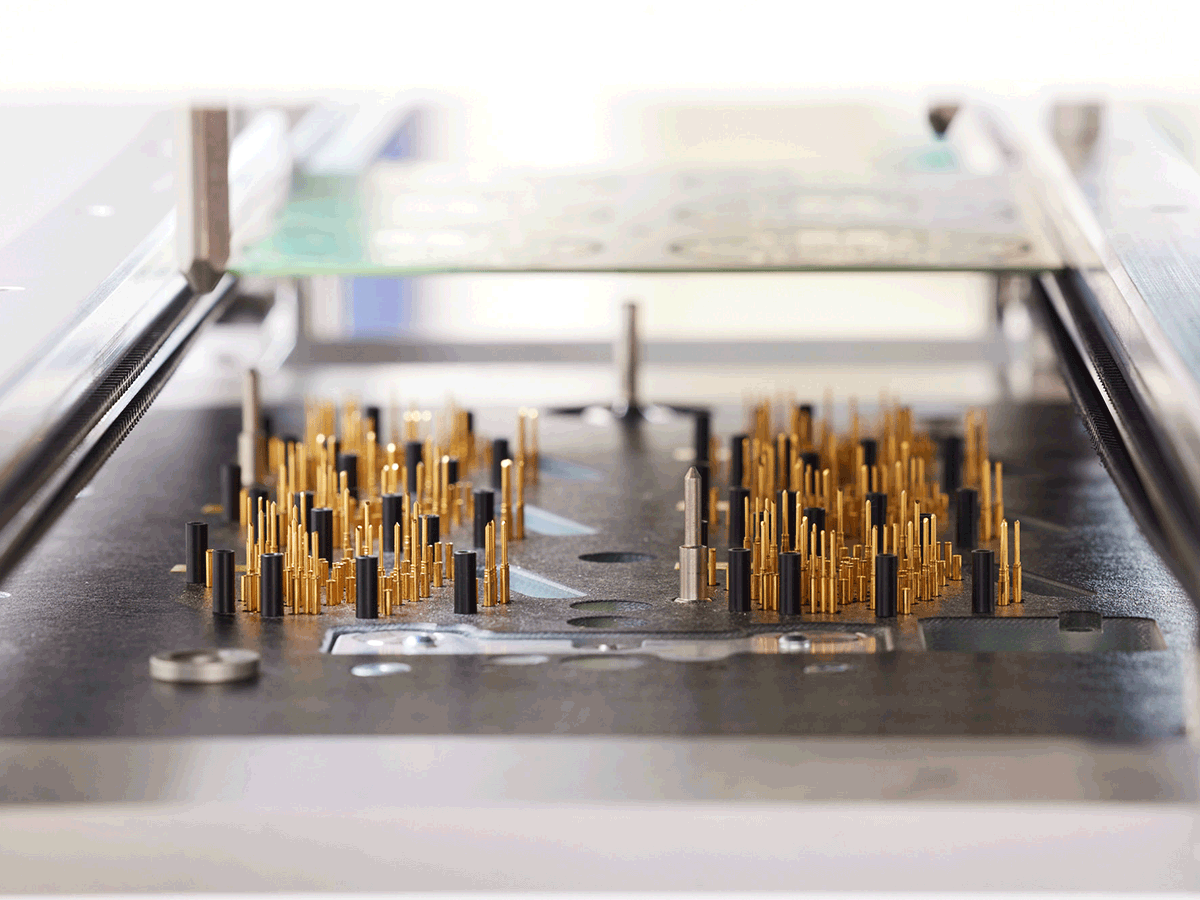

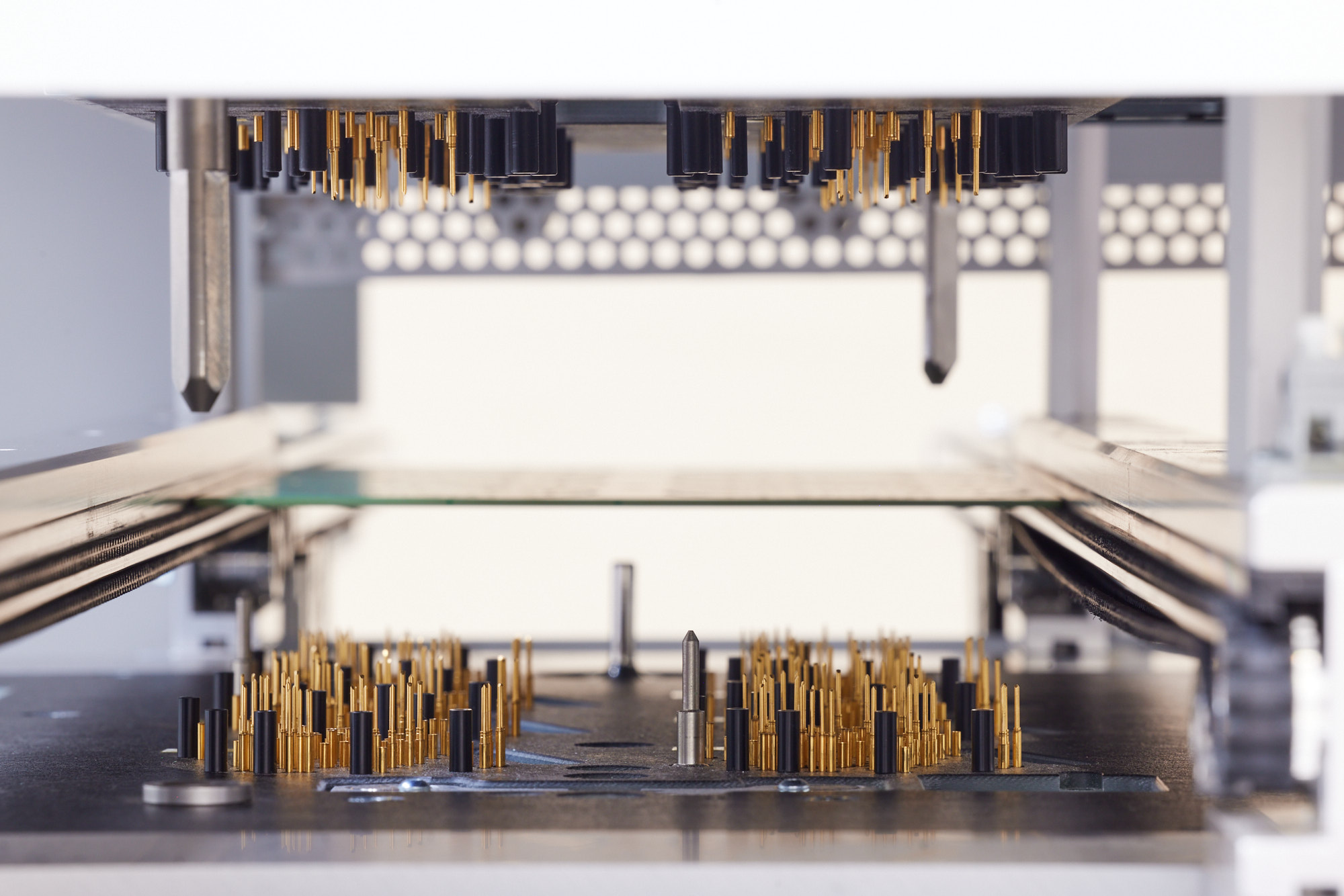

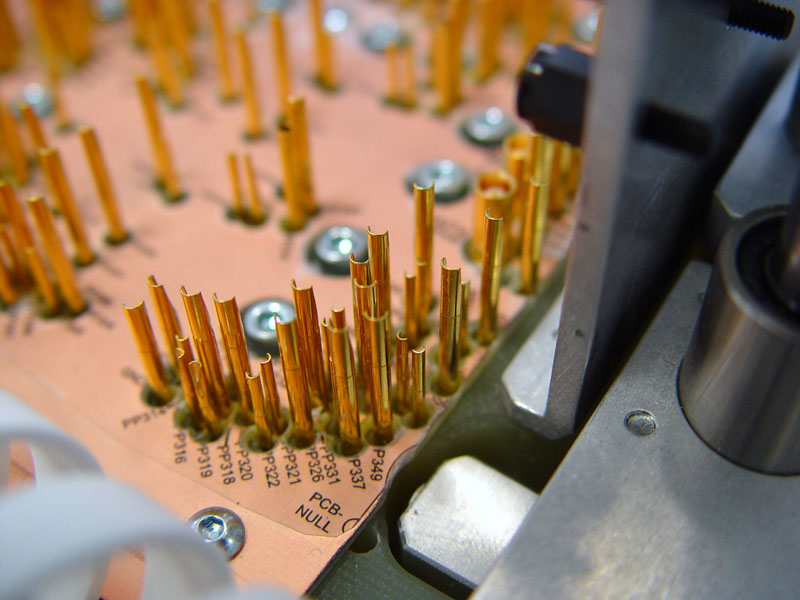

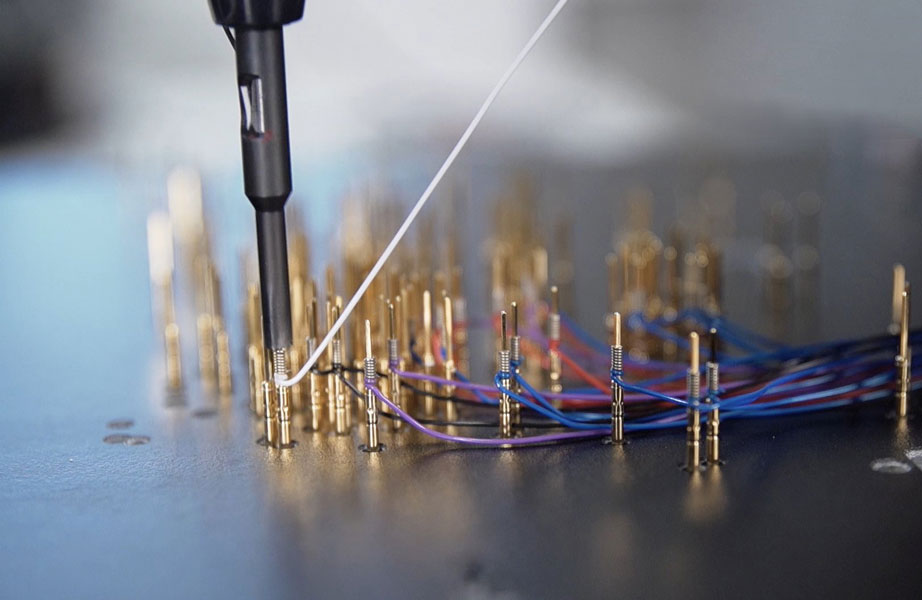

In an in-circuit test or functional test, assembled PCBs are contacted and tested via electrical measurements using special needles.

For this purpose, the PCBs or electronic products are contacted in the test systems in order to then forward the measurement signals to a connected test system. To allow the flexible testing of different DUTs on the same system, a product-specific contacting system is required: a “fixture kit”, i.e. an interchangeable, product-specific contacting fixture.

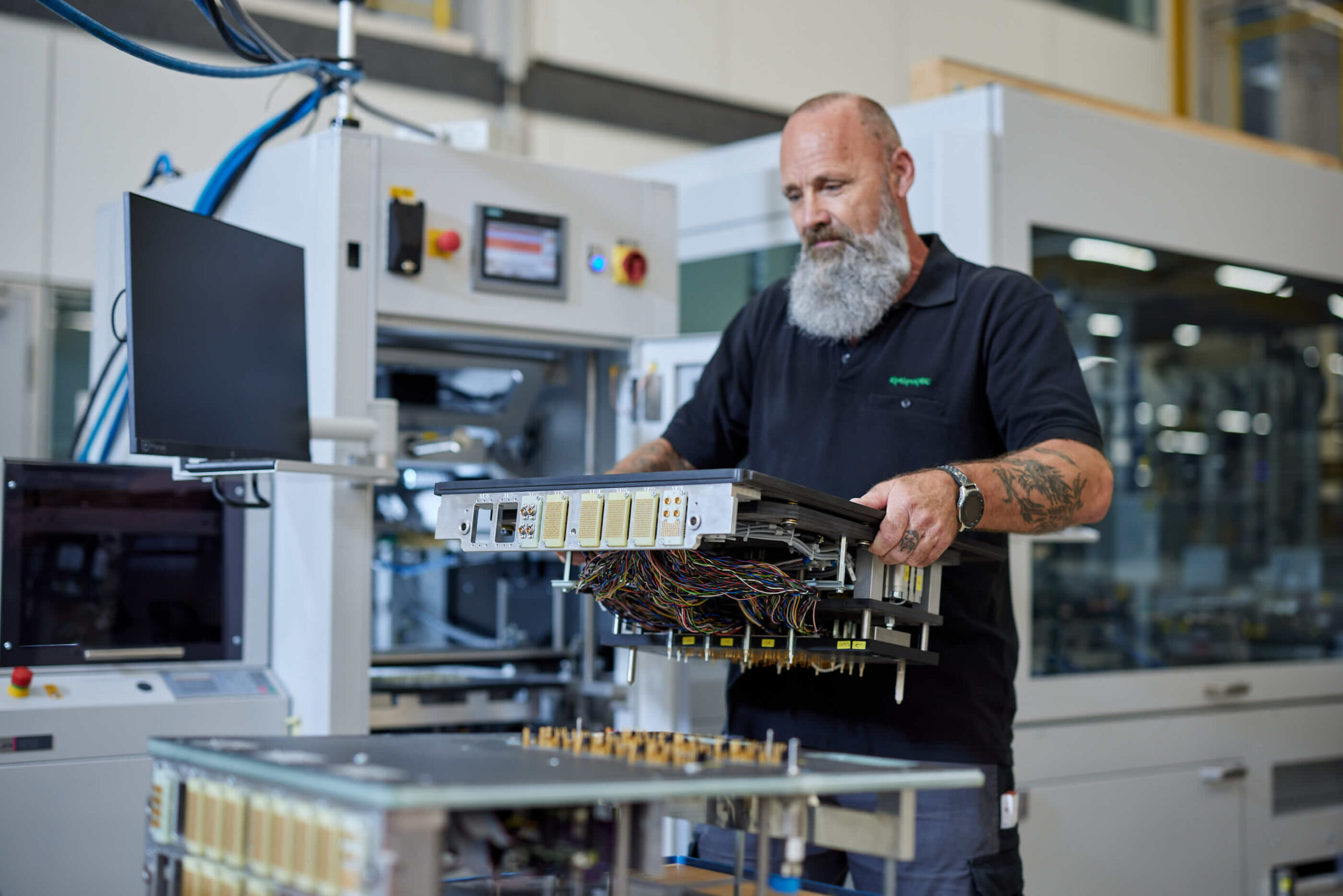

Like a drawer, the fixture kit can be replaced in a very short time, making machine changeovers fast and easy.

In an in-circuit test or functional test, assembled PCBs are contacted and tested via electrical measurements using special needles.

For this purpose, the PCBs or electronic products are contacted in the test systems in order to then forward the measurement signals to a connected test system. To allow the flexible testing of different DUTs on the same system, a product-specific contacting system is required: a “fixture kit”, i.e. an interchangeable, product-specific contacting fixture.

Like a drawer, the fixture kit can be replaced in a very short time, making machine changeovers fast and easy.

Hit accuracy

100%

when contacting

the test points

Number of test points

>1000

possible per fixture kit

Platforms

>5

from fixture to

stand-alone tester

to inline system

Characteristics

The devices are expanded according to the DUT. ENGMATEC covers the complete spectrum ranging from preparation of the DUT-specific data (drilling, milling, and wiring data) to mechanical removal and wiring.

Features

Testing of electrical signals, high-frequency signals, optical fibers, and much more

Automatic interlocks

Contacting, scanning, confirmation, readout, and programming via interchangeable fixtures

Lateral or additional contacting possible

Various interfaces ranging from pylon, ODU, VPC, and mixed forms to customer-specific interfaces

Manually or pneumatically operated desk adapters with fixture kit

Flexible modular system

Your advantages

Simple and fast changeover

Different test processes possible

Can be used in manual fixtures and inline systems

Wide range of possible DUT sizes

Step-by-step contacting possible for multiple test types

Product-specific expansion with additional electronics

Large number of interfaces for various connections

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.