Products

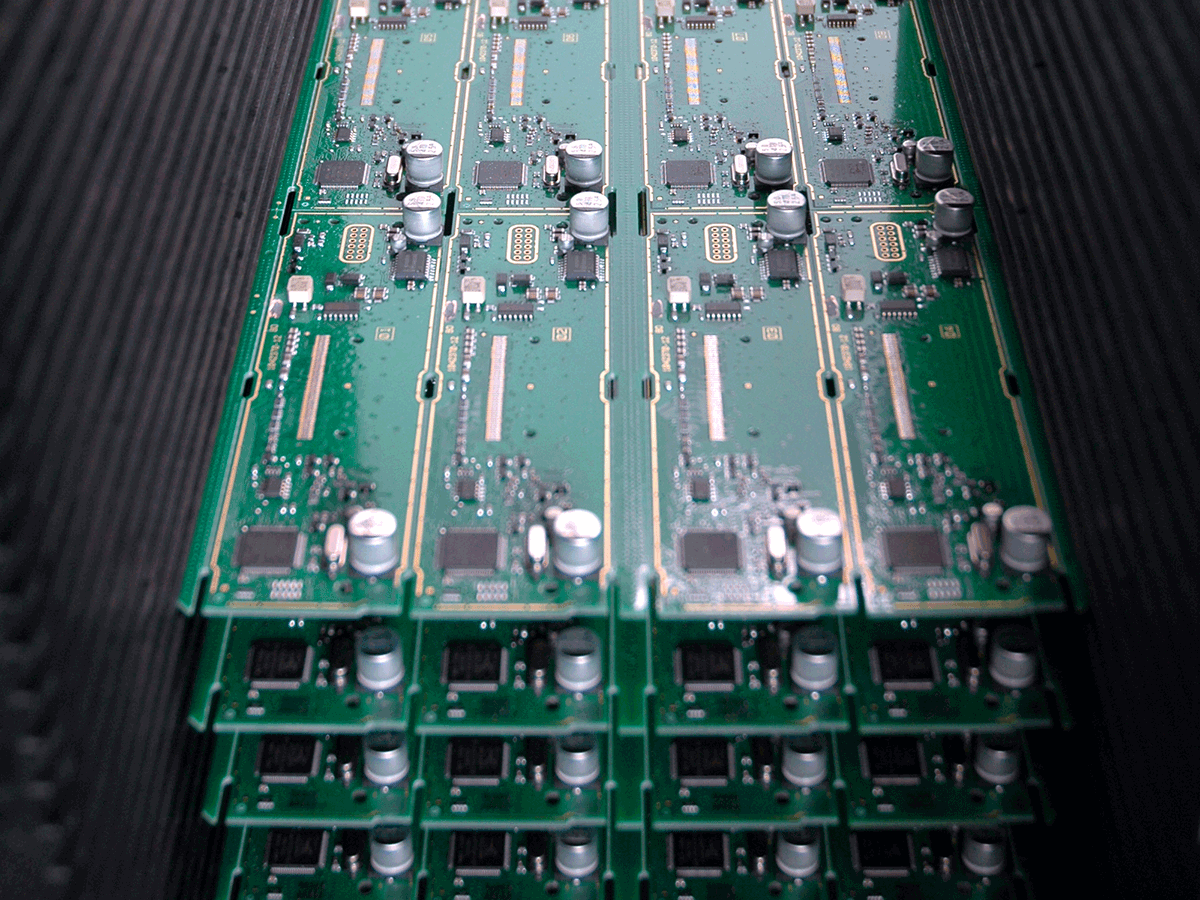

Board handling

At ENGMATEC, you can choose from an extensive standard range of tried-and-tested board handling systems for use in SMD lines, assembly systems, and test lines.

The modular system TECONA Move it! consists of various handling and transport systems for PCBs, solder frames, and workpiece carriers.

The transport widths, magazine types, and interfaces are assembled according to customer specifications. Depending on requirements, components such as soldering processes or vision systems can be integrated. Thanks to the particular flexibility of the standard modules, cost-effective adaptations can be easily implemented to meet special customer requirements.

At ENGMATEC, you can choose from an extensive standard range of tried-and-tested board handling systems for use in SMD lines, assembly systems, and test lines.

The modular system TECONA Move it! consists of various handling and transport systems for PCBs, solder frames, and workpiece carriers.

The transport widths, magazine types, and interfaces are assembled according to customer specifications. Depending on requirements, components such as soldering processes or vision systems can be integrated. Thanks to the particular flexibility of the standard modules, cost-effective adaptations can be easily implemented to meet special customer requirements.

Air consumption

0liters

as standard –

no pneumatic actuators

Service life

>20

years high quality

made in Germany

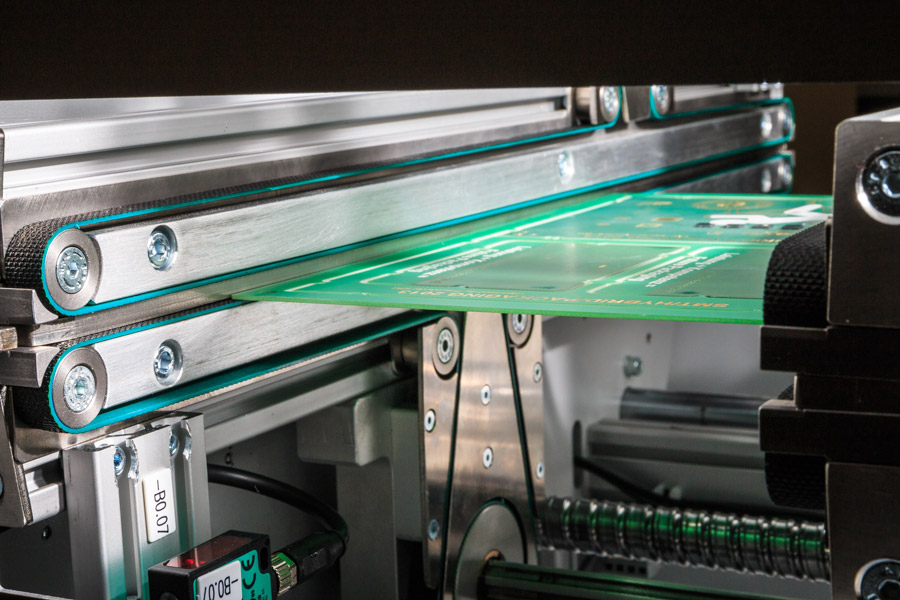

Belt speed up to

25m

per min

variably adjustable

Characteristics

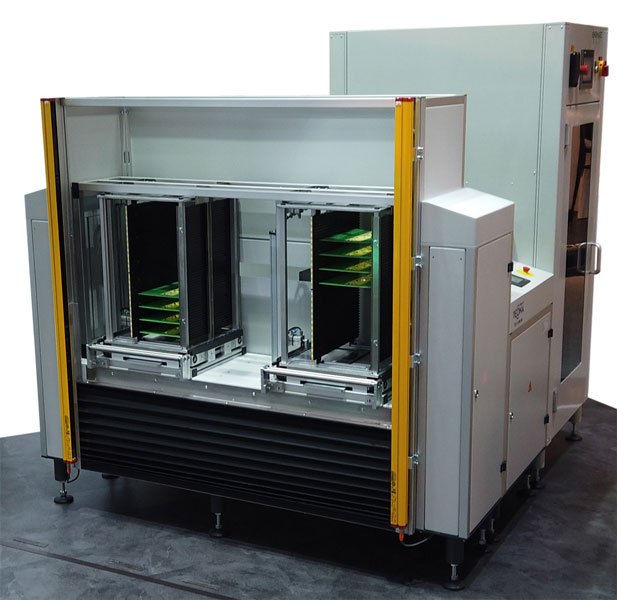

The product portfolio includes various loading and unloading stations with batch processing or with magazines. As a link between different components within a production line, all stations fulfill an important function.

Features

Stacking stations for processing unpopulated printed circuit boards

Magazining stations with one or more magazines depending on cycle times and production volume

Modules harmonized for combination with each other and with different production systems

Compensation of irregular cycle characters by process buffers

Functions including good/bad selection, cooling mode after thermal processes, LIFO or FIFO buffer mode, and prioritization of time-critical processes

Handling systems such as lift stations, turning stations, reversing stations, or horizontal transfer stations

Cleaning stations and scanner belts

Simply request the product information now.

Fill in the fields above. You will then receive a download link by email.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum.

Your advantages

Robust and compact design

High speed and accuracy

due to servo motors

Longer service life

due to brushless driven motors

Low wear

due to hard-chrome plated guide shafts

Customized modifications

Easy integration

due to open interfaces

Highest safety standard

AMR capable

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.