Case study

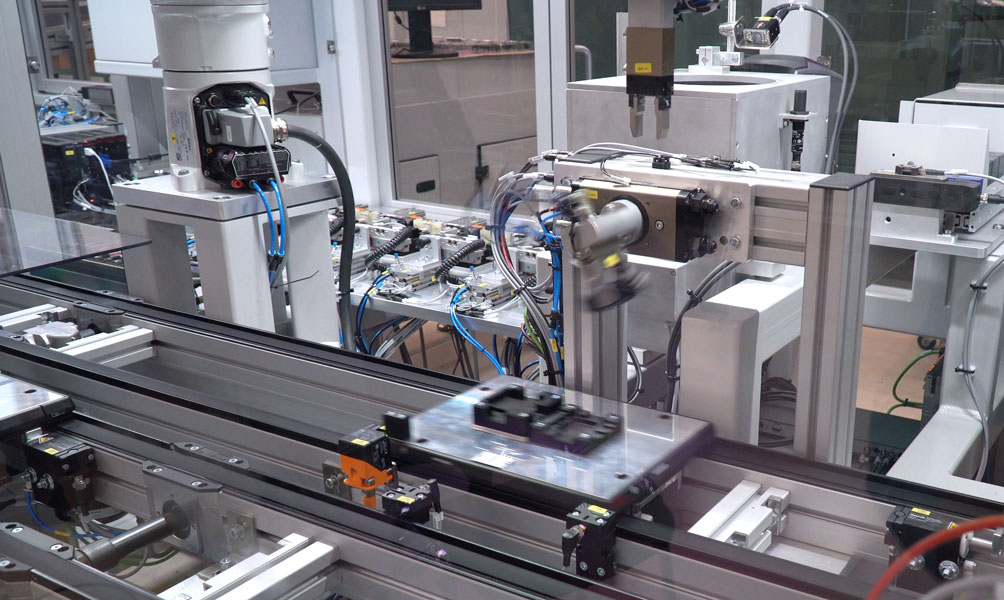

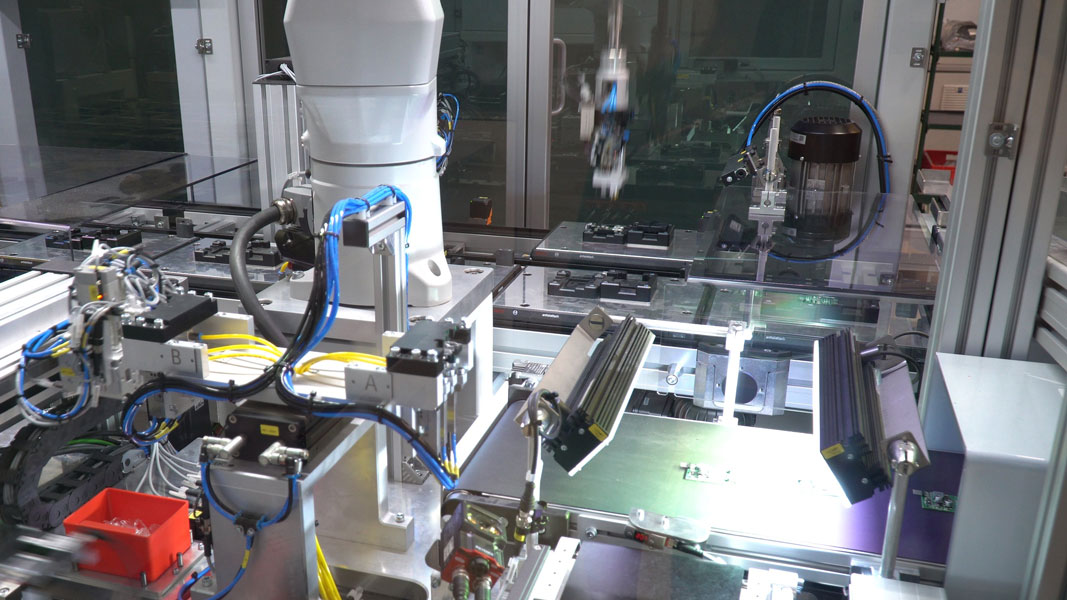

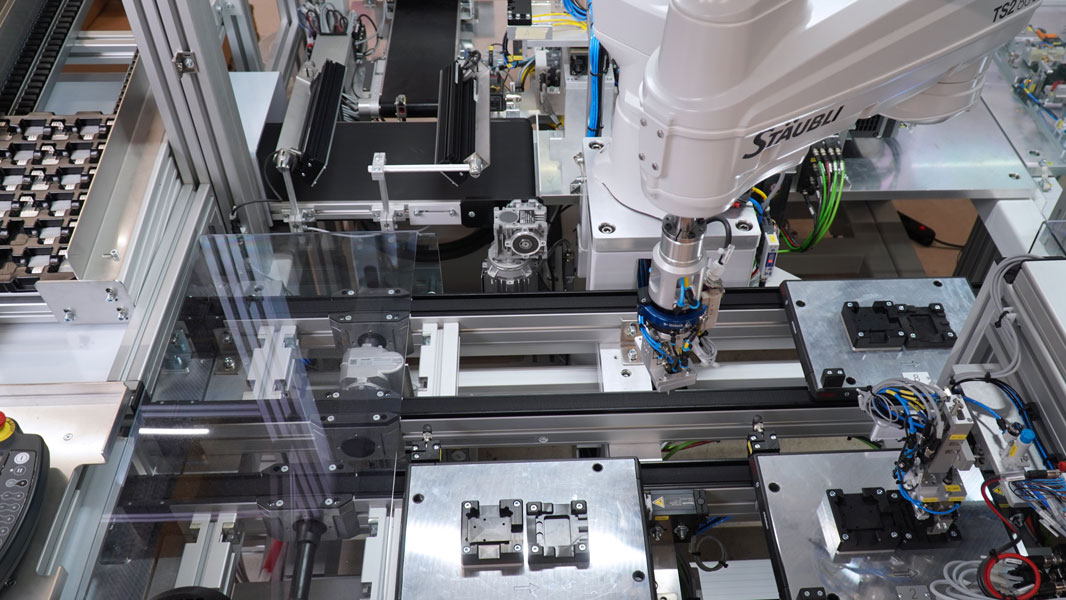

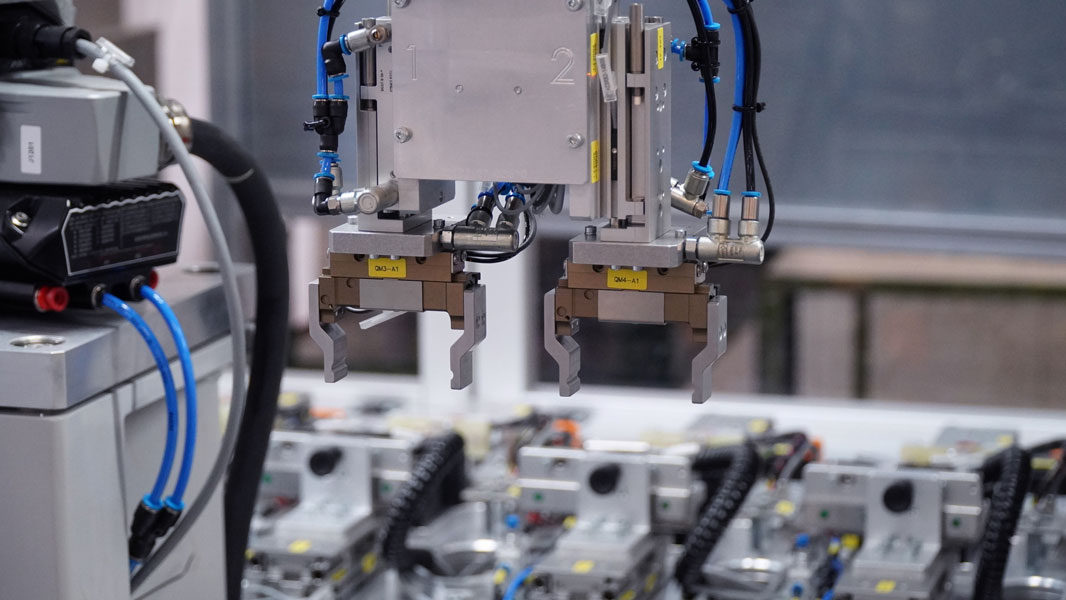

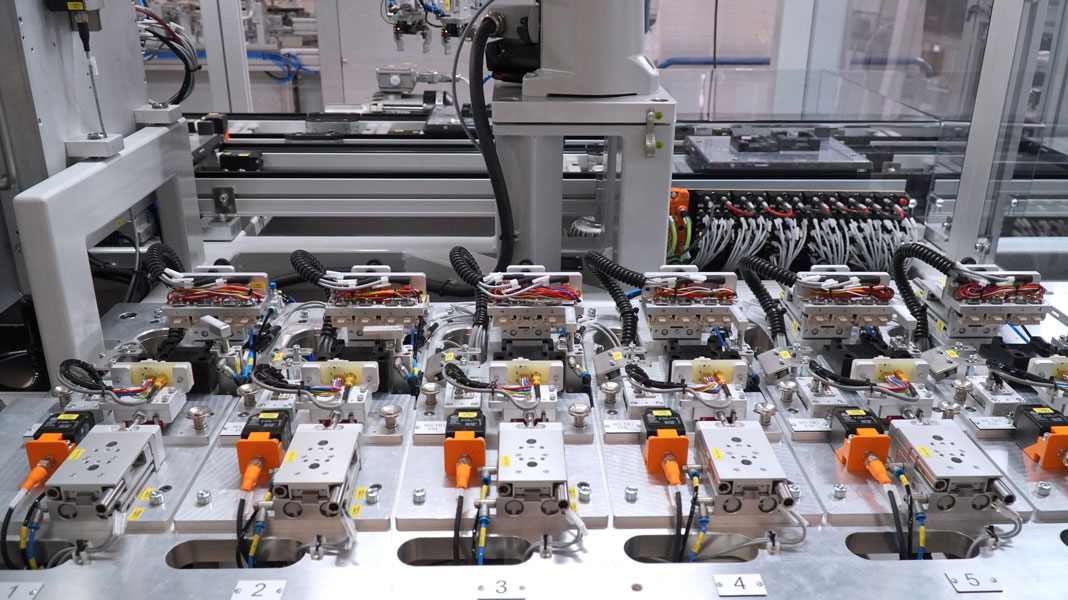

Assembly and testing of USB charging ports

USB charging ports in cars are used as a quick and reliable means to charge electronic devices or connect them to the vehicle. One of our customers required a solution for assembling and testing just such charging ports.

The task was to integrate many processes within a confined space, including packaging and labeling, and to adhere to a cycle time of only 7 seconds.

The system also had to be designed in such a way that further lines utilizing the same concept could be set up for other products, while ensuring uniformity in layout and operation.

Cycle time

7s

due to parallel processes

and bypass function

Setup time

10min

due to intelligent

quick change system

Self-sufficiency

30min

due to sufficient buffer

capacities for the material

Our

services

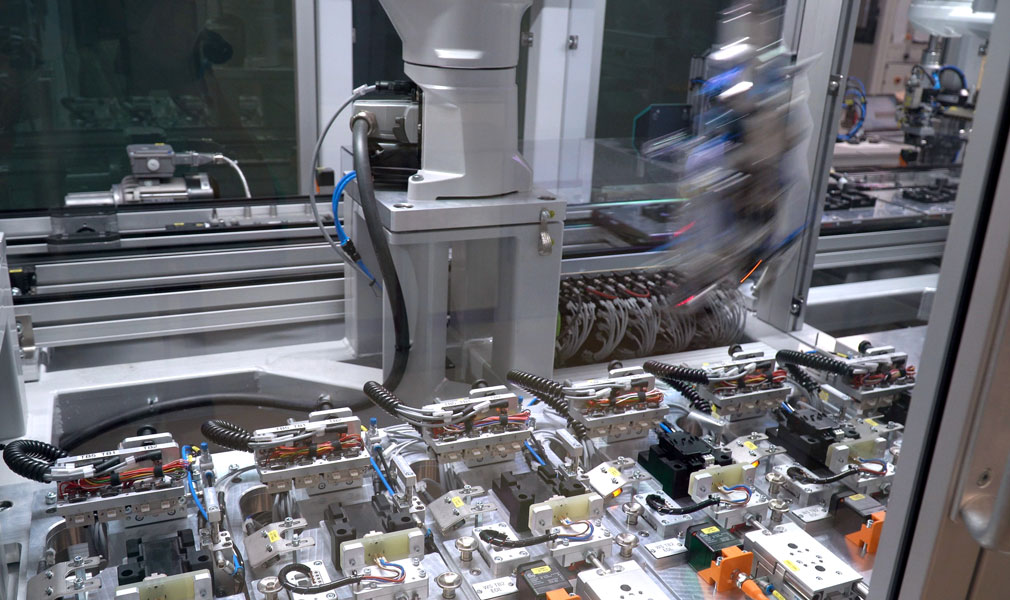

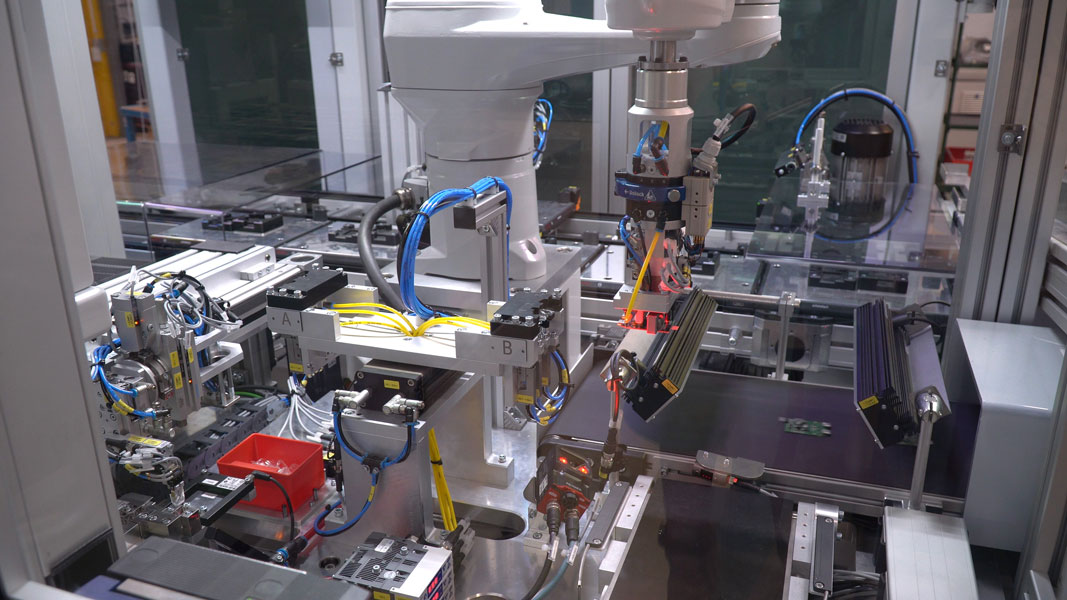

ENGMATEC developed a fully automated assembly solution with end-of-line testing offering a space-optimized design with integrated standard processes. A short cycle time is achieved through parallel testing in ten EOL test stations. In addition, an intelligent bypass function aids in reducing the lead time – with no major capital expenditure required.

Your advantages

Low space requirement

thanks to space-optimized solution

Savings

due to reusability

Short cycle time

due to parallel assembly and testing processes

Turnkey docking of the line

to upstream production system

Can be reused

for seat control, convertible top control, inductive charging cradles, and more

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.