Case study

Hot/cold thermal test system

To ensure the safety of vehicle occupants, the cold and hot testing of electronic assemblies in passenger cars are of crucial importance. This is because, throughout a car’s life cycle, thermal stress poses a particularly great challenge. Components can fail at very high or low temperatures, resulting in the failure of entire systems. However, the electronics in safety-critical components in particular must also function under extreme conditions.

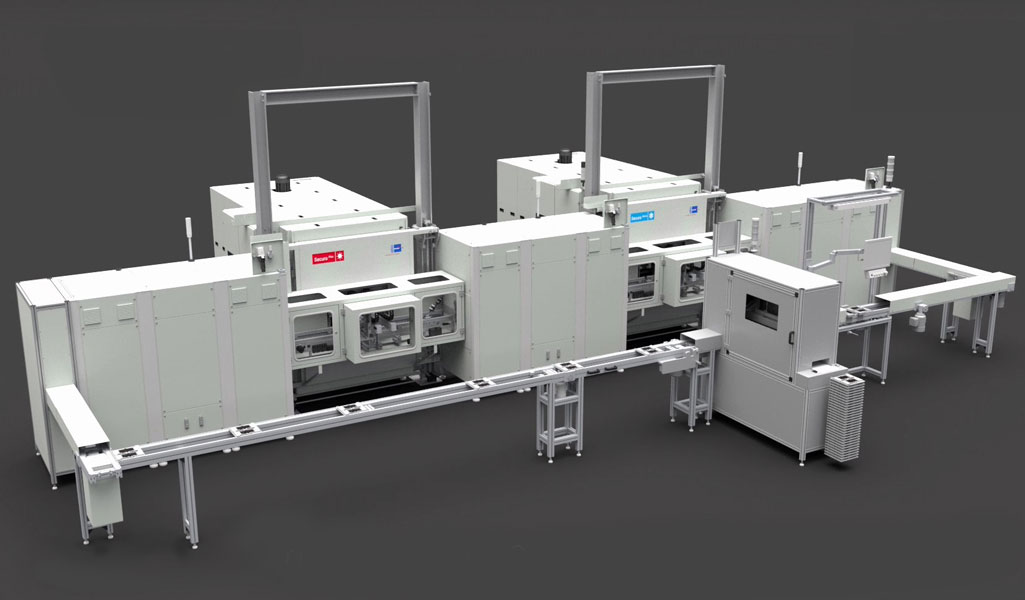

One of our customers faced the challenge of ensuring this. To meet this challenge, a fully automatic continuous system for temperature testing was required. The customer had to test the power electronics for an on-board voltage system.

In the cold and hot tests, the electronic components are subjected to loads ranging from −40 °C to +140 °C.

Cold

−40°C

Functional tests

of electronic assemblies

Heat

+140°C

Functional tests

of electronic assemblies

Safety

100%

under extreme load

Our

services

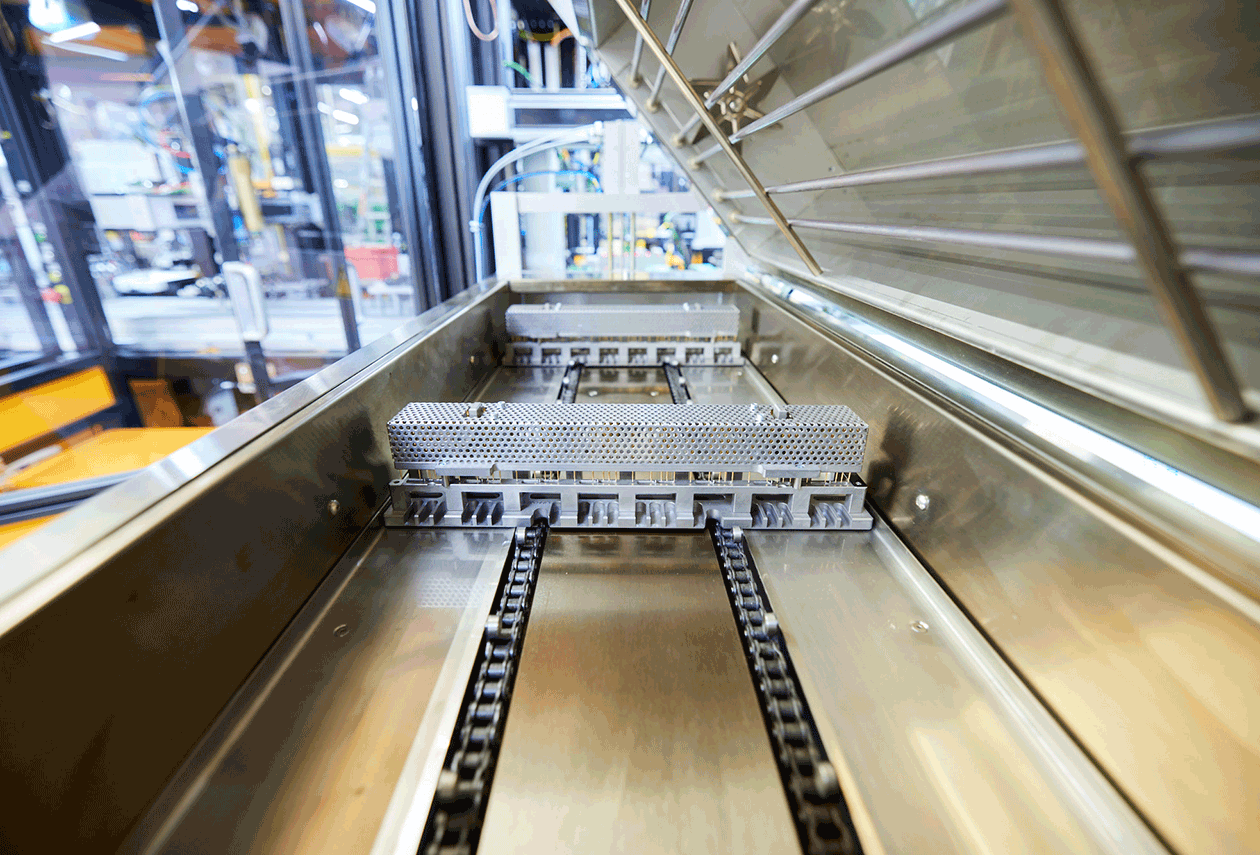

ENGMATEC designed a circulating system for the functional testing of components at different temperatures. High-precision inline testing with passive product temperature control from −40 °C to +140 °C was implemented as a continuous process. This made it possible to already detect possible product defects during the manufacturing process, thereby eliminating any risk.

The solution enables the customer to dock its own product-specific test system. Furthermore, it also allows the configuration of expansion stages for a system with active temperature control during long cycle times according to the framework parameters.

Your advantages

Ensuring the function

of safety-critical electronics

Low manpower

required for loading due to fully automatic line

Simple integration

with intralogistics

Can also be applied

for battery management, control electronics, fuel cells, and more

Defective product components detected early on

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.