Products

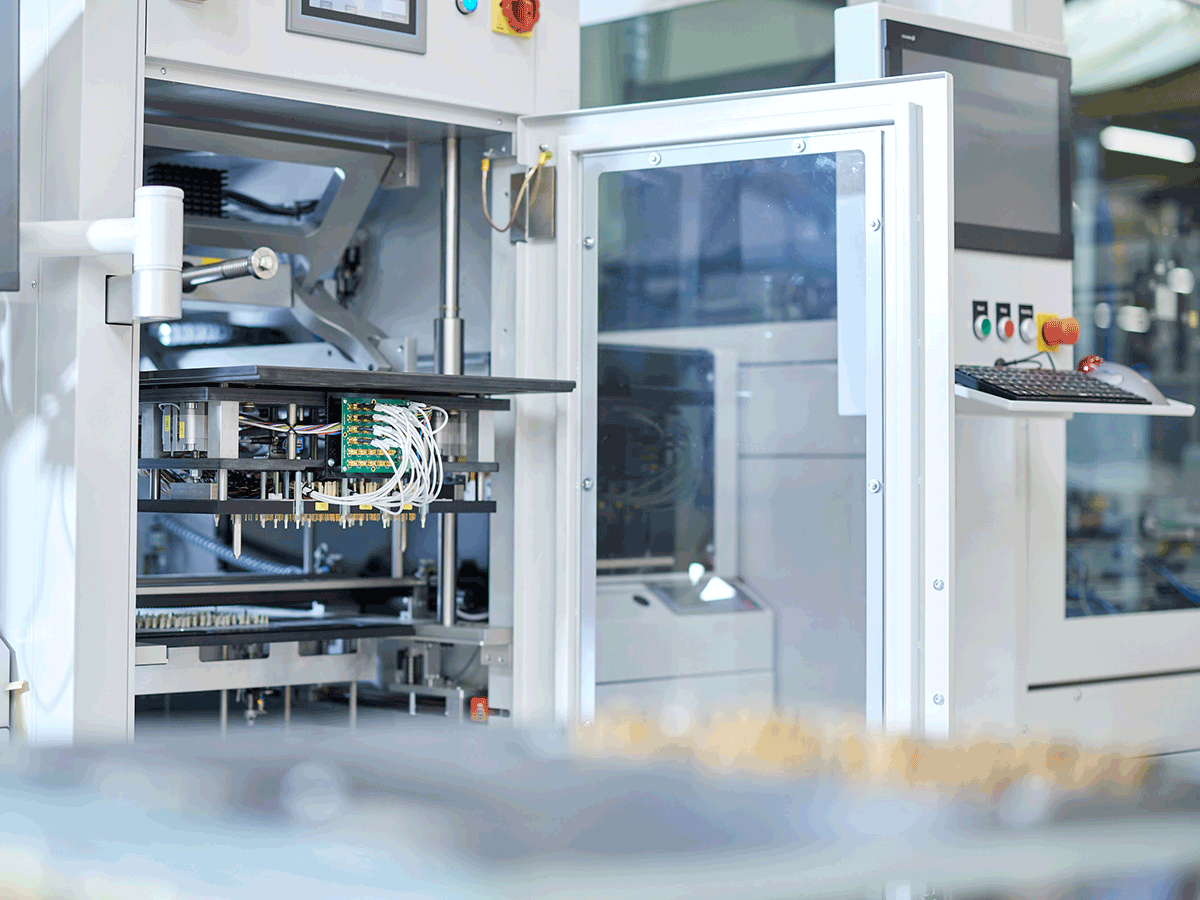

ETH test handler

Our modularly designed range of test handlers gives you cost-effective solutions for a wide variety of testing tasks, such as in-circuit, functional, and final tests. They also allow the integration of vision systems, scanners, marking devices, and many other components.

Different feeding alternatives for single circuit boards, boards in trays, or boards in assembled panels can be set up individually thanks to the track adjustment, thereby ensuring maximum flexibility even with new requirements.

The systems can be used as stand-alone systems or integrated in assembly and test facilities, with interfaces used to connect them to higher-level data systems such as MES or ITAC.

Our modularly designed range of test handlers gives you cost-effective solutions for a wide variety of testing tasks, such as in-circuit, functional, and final tests. They also allow the integration of vision systems, scanners, marking devices, and many other components.

Different feeding alternatives for single circuit boards, boards in trays, or boards in assembled panels can be set up individually thanks to the track adjustment, thereby ensuring maximum flexibility even with new requirements.

The systems can be used as stand-alone systems or integrated in assembly and test facilities, with interfaces used to connect them to higher-level data systems such as MES or ITAC.

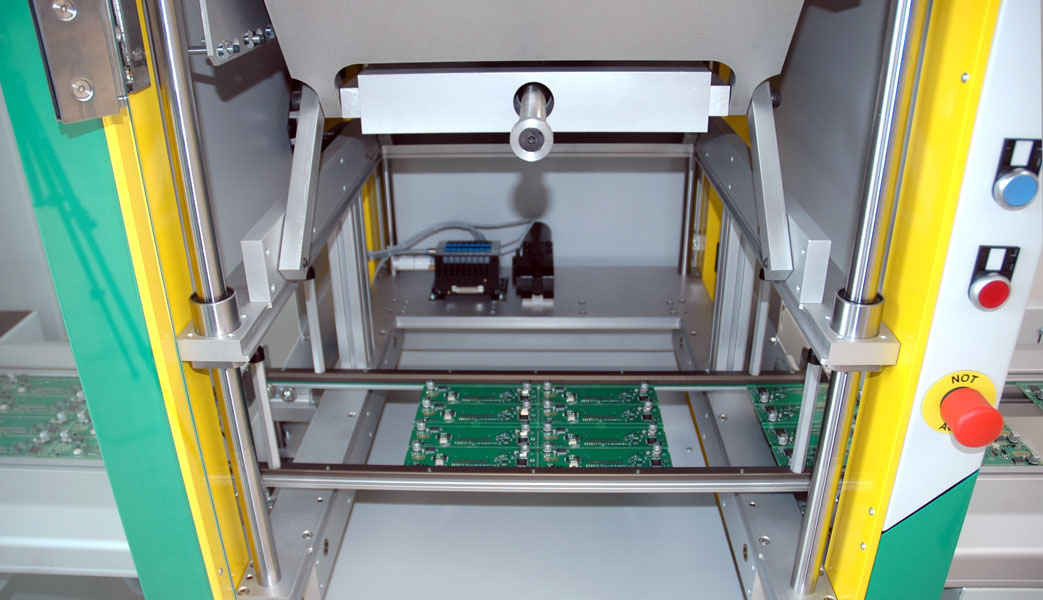

Contact force up to

6000N

per fixture kit interface

on bottom and top

handling time

>3s

for PCBs

or workpiece carriers

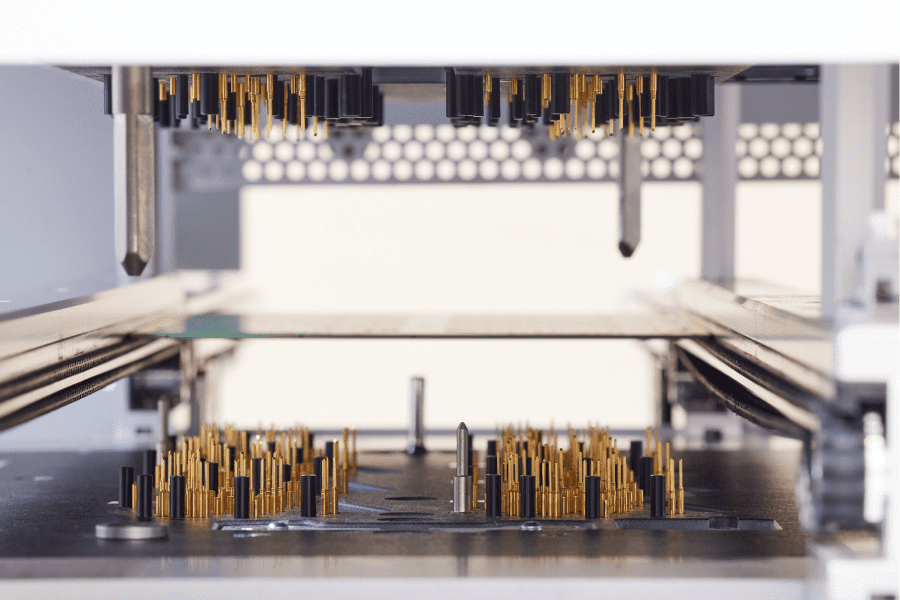

Test point grid dimension from

1mm

with a pad diameter

> 0.5 mm

Characteristics

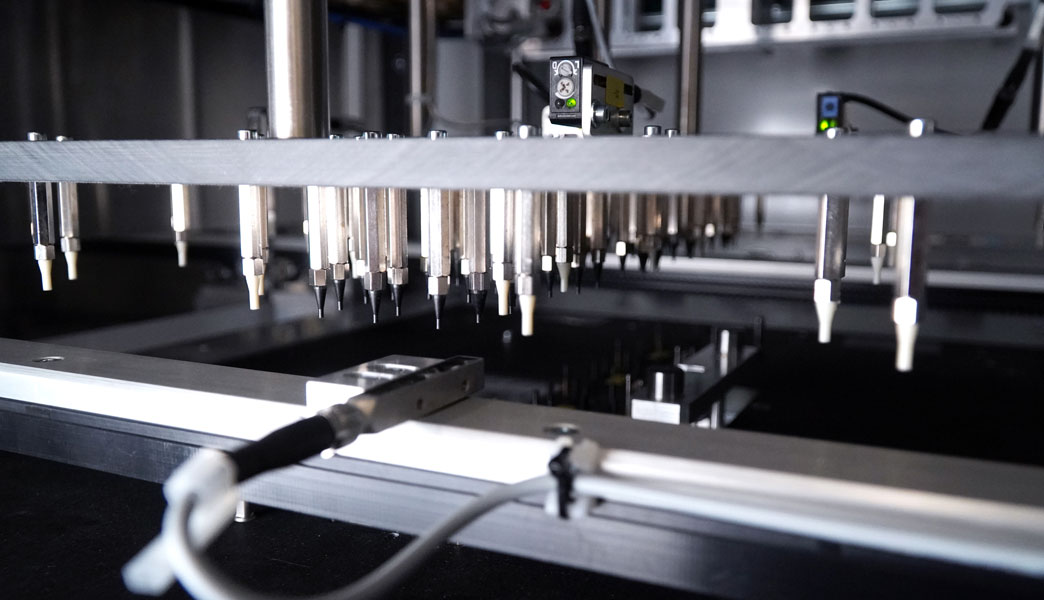

The test cell is used for in-circuit, functional, and final testing. The contacting of the PCBs can be achieved on one side or on both sides, as well as step-by-step in the case of multiple panels.

Features

Variable contacting strokes by means of toggle lever mechanism, spindle drive, and AC servo motor

Transport width manually adjustable from 50–400 mm

Short set-up times due to automatic fixture kit loading and locking device

WS interfaces bottom and top

Barcode scanner

Space for 19″ rack for measuring equipment

Customized interface from basic unit to fixture kit

Simply request the product information now.

Fill in the fields above. You will then receive a download link by email.

Your advantages

Stable mechanics

Synchronous, continuous force application

Flexible for future applications

Short set-up times

Automatic width adjustment

Compatible with all standard production systems

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.