Competences & Products

Testing technology

At ENGMATEC, you will find a comprehensive range of reliable test solutions for your electronic product – from PCB testing to integrated solutions.

Benefit from our experience and expertise as well as the wide range of technologies that we use.

We design test systems for large or small series production based on the needs of our customers. Required processes related to electronics, image processing, mechanics, and pneumatics are selected and combined in a targeted way. The selection process depends on product-specific factors such as production volume and complexity.

Our products for testing technology

ETH test handler

System for testing printed circuit boards and electronic assemblies for in-line integration

more

Test fixtures

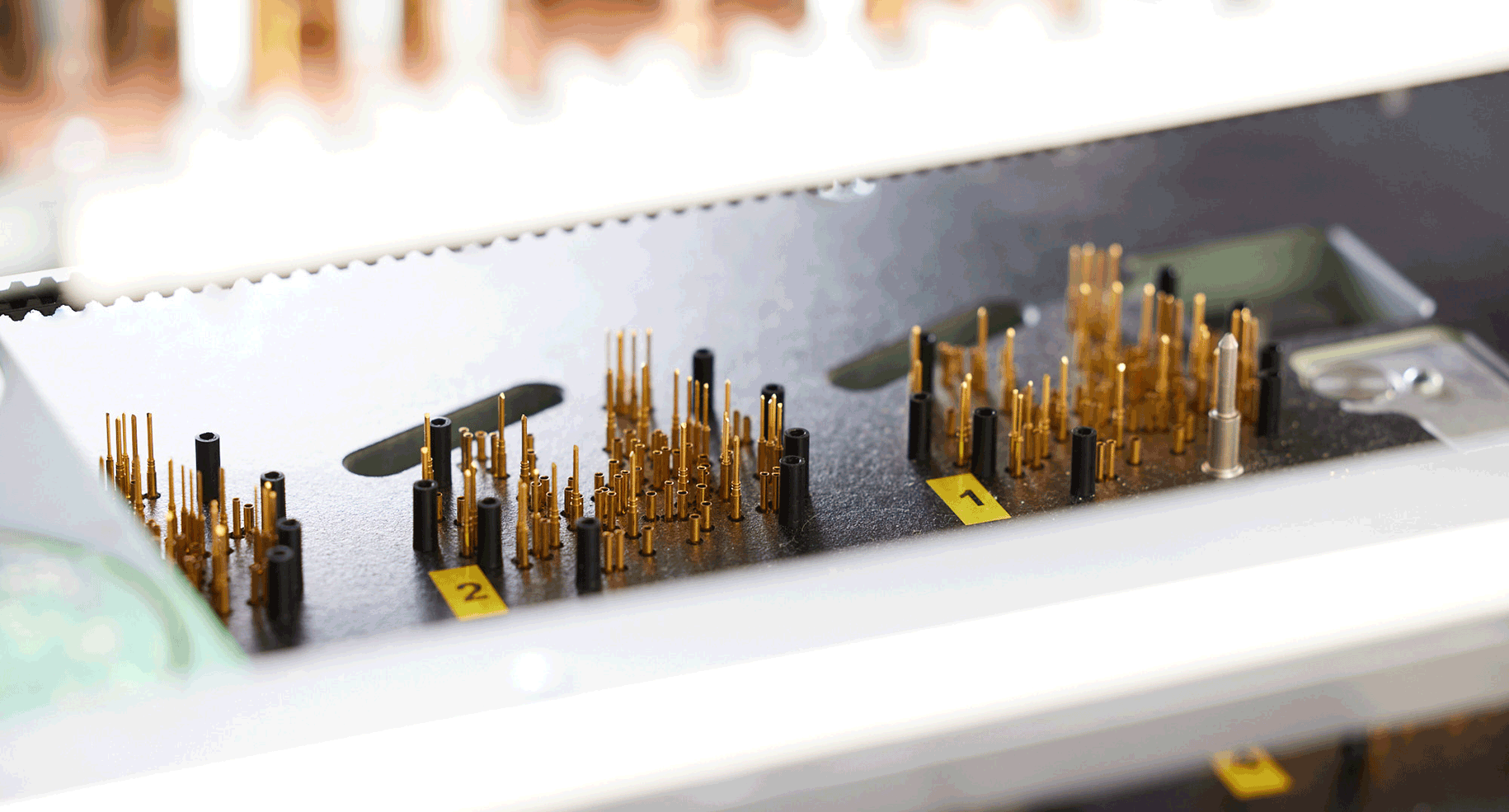

Contacting systems and desk fixtures for testing assemblies and devices

more

Test connectors

Industrial-grade contacting connectors for testing the most common interfaces

more

RF test chambers

Test cells for testing assemblies in the high-frequency range in a shielded environment

more

Smart Contact Cell

Stand-alone test equipment for ICT and FCT testing with parallel feeding and removal

more

Board handling

Handling and transport systems for printed circuit boards, solder frames, and workpiece carriers

more

Temperature test chamber

Checking the functionality of communication modules under certain temperatures

more

High temperature test cell

Test station for the functional test of printed circuit boards, panels and assemblies up to 140°C

more

Perfect for the following areas

In-circuit test

In the in-circuit test, assembled printed circuit boards or electronic components are contacted and tested for defects in the circuit path, such as short circuits or interruptions, solder bridges, and component defects.

In the process, each node in the circuit is tapped via a test needle. “Bed-of-nails test fixtures” are employed for the automated contacting of these test points.

Functional test

During production, the quality of the devices or assemblies must be checked either in intermediate steps or at the end of the manufacturing process.

For the functional test, existing interfaces that are externally accessible (e.g. connectors) are generally used for this purpose. Special test fixtures are used for contacting.

This makes it possible, for example, to check sensors or controllers.

Flashing

Together with our partners, we offer integrated solutions for flashing your products.

For flashing, the product-specific software is installed in the product. Alternatively, we also integrate your customer-specific system into our test systems.

We offer the flash process with our standard products as well as an integrated process for your specific solution.

End-of-line test

For the final complete functional test of finished products and assembled components, we offer end-of-line test systems. This is the test performed at the end of a production line.

For this purpose, various environmental conditions may have to be simulated. Processes such as the application of labels are also checked.

The EOL testers can be configured for any requirement and provide traceable test results.

Haptic test

To ensure product functionality, we integrate haptic testing into our automation solutions.

The end customer touches and operates the product, while our test equipment ensures the proper feel and function.

Be it a button, a knob or a touch surface – we ensure its function with precision.

RF test

Test systems for high-frequency devices are used for testing products employing radio transmission.

The systems are designed for modules with frequency ranges from 300 MHz to 96 GHz. In addition to communication modules, these also include products with radar sensors for autonomous driving and car communication.

To rule out interference during testing, the test area must be shielded against external influences such as mobile radio communication or other interference pulses.

Temperature test

Defects that occur under extreme loads should be detected as early as possible in manufacturing processes. This is made possible by “temperature tests.” To perform these tests, the products are tested in the temperature test systems by being exposed to various thermal and mechanical stress factors, depending on the requirements.

Our product range includes both stand-alone systems (test chambers) and automated simulation lines.

High current test

ENGMATEC develops and implements reliable contacting for high voltages and currents of up to 1000 V and 400 A. Such contacting is of increasing relevance, especially in the areas of electromobility, battery management systems, and drive technology.

They are required, for example, for testing inverters, DC/DC converters, and drive controllers.

AOI image processing

Optical systems are frequently used in modern test and assembly equipment.

From simple or complex detection tasks to quality checks and intelligent camera technology, we will work with you to determine the right system to meet your requirements and select the components accordingly.

Example applications include wobble circle tests, testing of component features, and camera-supported joining processes.

Your advantages

Concentrated know-how

through assembly and testing expertise from a single source

Flexibility

through custom solutions

Experience

from more than 2000 realized projects

Reliability

for the end user through tested quality

Efficiency

through cost-effective concepts

Savings

through reduced manpower requirements

Transparency

in the production process

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.