Case study

Control unit for driver assistance systems

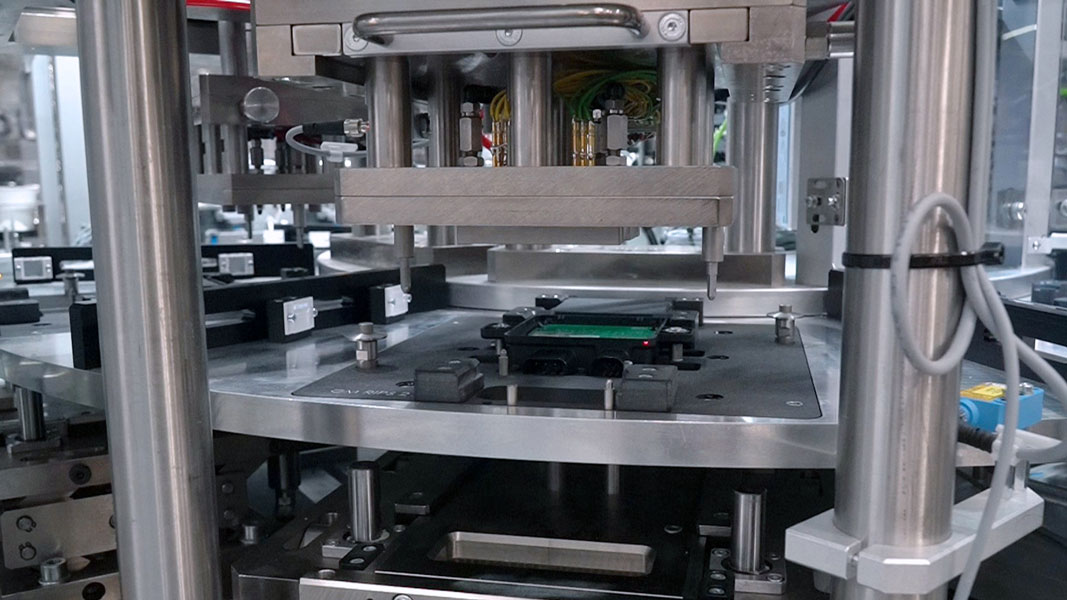

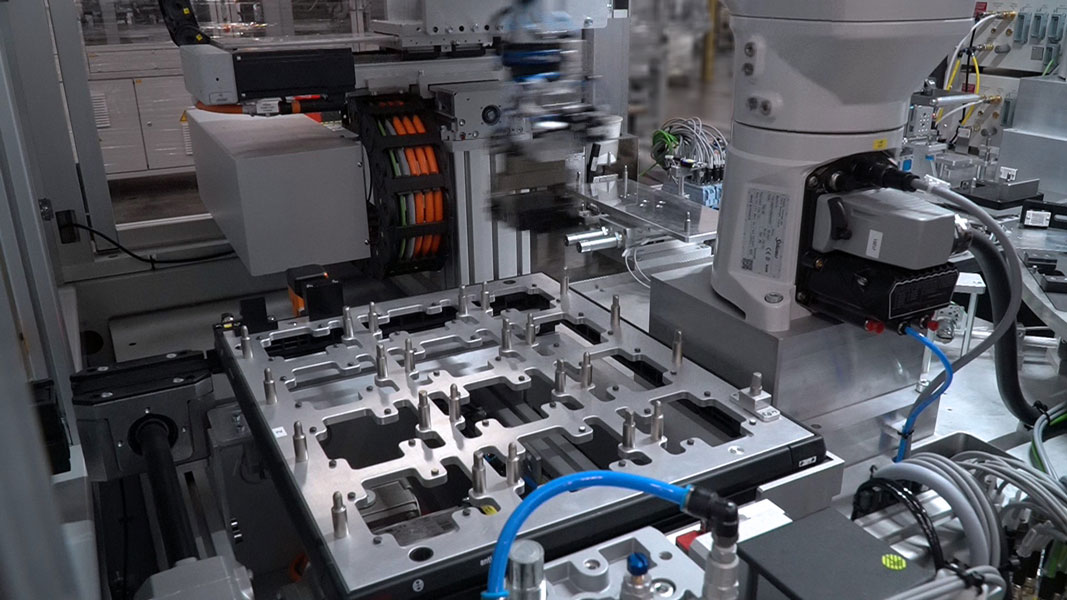

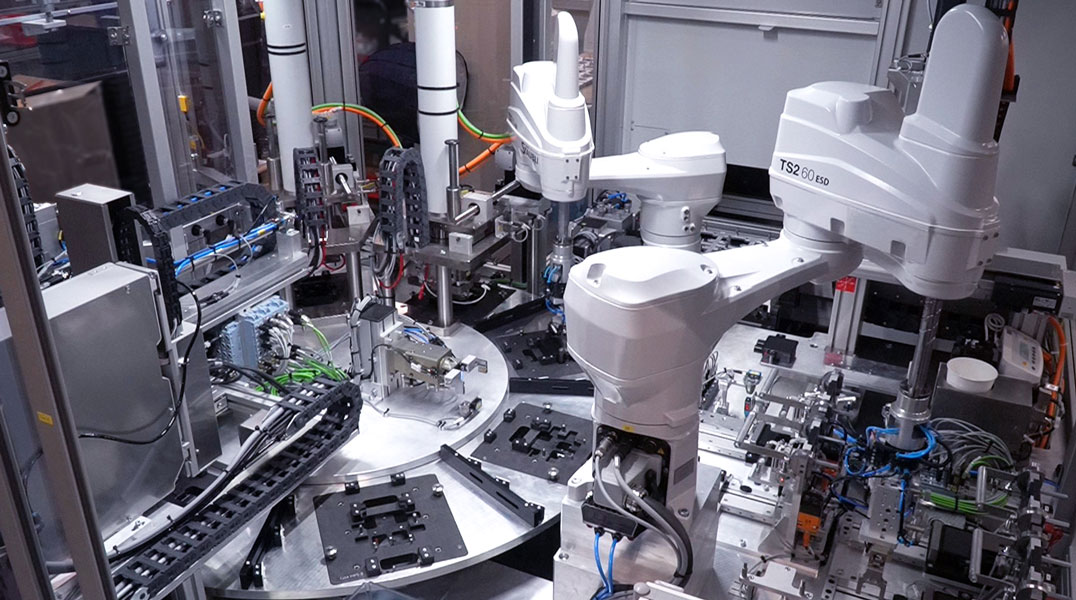

A customer contracted us to perform automated assembly and end-of-line testing of a control unit for driver assistance systems. It was also to check for leaks and handle other processes, such as packaging and labeling. Process automation had become necessary to create a link between temperature-dependent processes and ensure their proper sequence.

A special challenge here was the very limited available space. In addition, testing had to take place in a test environment that was shielded from the surrounding environment, free of interference, and reproducible.

Cycle time

25s

through optimally

timed processes

Footprint

2x2m

compact design – low space requirement

Processes

7

in a highly confined space

Our

services

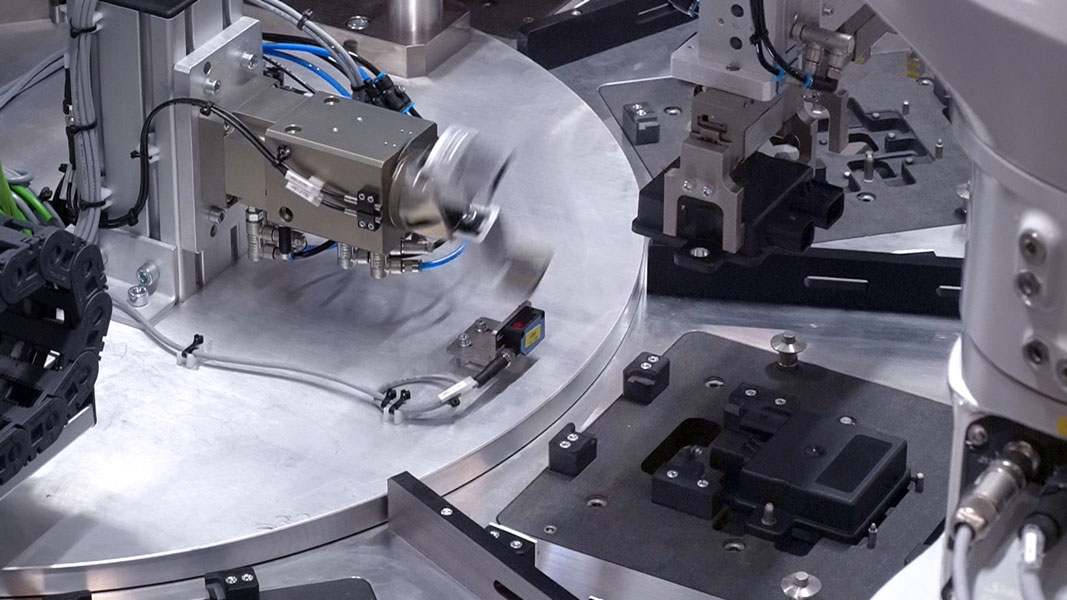

ENGMATEC developed a rotary indexing table that combines all processes from press-fitting, including redundant force-displacement monitoring, to dispensing, curing, and packaging. In addition, it tests the products – as requested – for leak-tightness and function.

The compact system requires only limited staff to operate and features interfaces in the product fixtures allowing future use with related products.

Your advantages

High flexibility

due to modular design

Further use possible

Minimal setup effort for product variants

Effectiveness

due to quickly changeable fixture kits and product carriers

Low space requirement

due to compact design

Process reliability

and reduced defect rate due to automation

Low manpower

required due to automation and simple operation

Do you have individual requirements?

We will find the right solution.

From process analysis to the finished system.